views

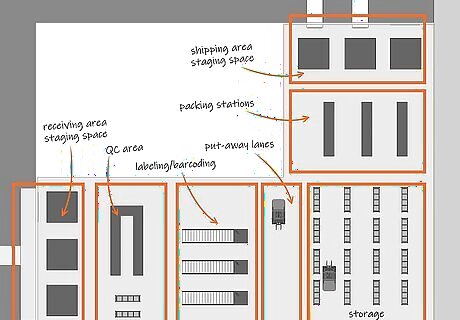

- Prepare a receiving area with vehicle docks, a staging space for deliveries, a place to catalog and update inventory, and put-away lanes to transport goods.

- Set up packing stations in the warehouse’s shipping area, and stock them with supplies for packaging and transporting products to customers.

- Plan areas ergonomically, making them as comfortable and convenient as possible for workers, and track warehouse stock with inventory management software.

Shipping & Receiving Area Overview

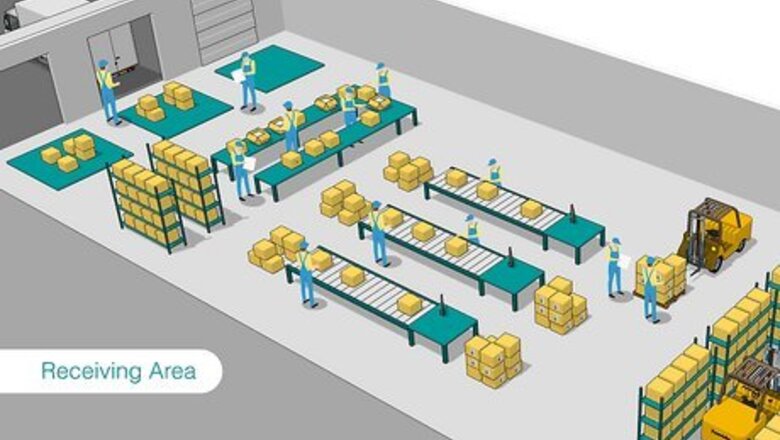

Receiving areas are the first stop for incoming goods at a warehouse. Incoming inventory arrives at the receiving area, where it gets processed and inspected before being moved to storage. Setting up a receiving area (and the warehouse as a whole) as efficiently as possible can help speed up the flow of products from one point to another. The main parts of a receiving area are: Delivery: Where materials and products are dropped off at the warehouse. Inspection: Where received materials and products are checked out to ensure they’re of good quality and not damaged. Organization: Where received materials and products are organized before being moved to storage.

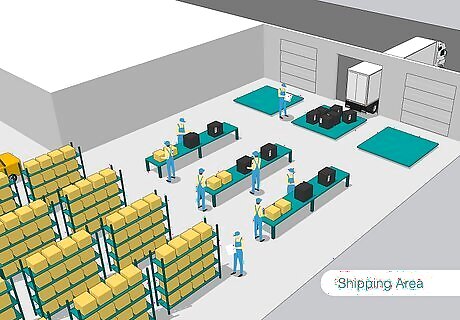

Shipping areas are where products get packed before being dispatched. A warehouse’s shipping area is the final stop for all goods after they’re picked. Shipping areas usually consist of packing tables (or shipping stations), which contain all the different materials needed for packing and shipping goods, and workers package the goods that need to be shipped. Shipping areas typically also contain loading docks, where packages are loaded onto vehicles for shipping, and a staging area for outgoing packages to be organized.

Establishing a Receiving Area

Prepare enough docking space to handle large deliveries. The first major component of a receiving area is the delivery space, which usually includes docks, where delivery trucks can connect to the warehouse to unload goods. Verify that you have enough docking stations and the right equipment to handle the number of incoming shipments that you’re expecting at your warehouse. Invest in the equipment you’ll need to manage incoming shipments. For example, you may need a hand cart or conveyor to unload items. Or, a forklift or pallet cart may be necessary if shipments are usually delivered on pallets. If possible, keep the incoming and outgoing docks in separate parts of the warehouse. Just as incoming docks are a key part of the receiving area, outgoing docks are part of the shipping area—and separate docks may help to eliminate any potential conflicts or issues between inbound and outbound shipments.

Reserve a staging space big enough to unload and inspect goods. In a staging space, incoming shipments are unloaded and placed temporarily before they’re processed, organized, and sent to storage. It’s important to have a big enough staging space at your warehouse, not only so that incoming shipments have a place to go when unloaded but also so employees have space to inspect delivered goods. Consider the volume of goods you expect to receive, and then block out adequate space to keep those goods for your staging area. Inspections are an important part of making sure you receive the correct items in the right quantities or weight. For example, employees could use the staging area to check the packing slip and count boxes to ensure everything is in order.

Create a quality control area for storing damaged goods. Quality control matters, both when shipping items out to customers and receiving them at the warehouse. After all, you can’t use damaged products; it’s more efficient to sort through everything after delivery and separate broken products from usable products. Designate part of the receiving area to hold damaged items until they can be returned or thrown out. Companies usually have benchmarks for damaged goods, meaning they expect a certain amount won’t pass quality control standards, which is why it’s a good idea to anticipate this and set aside space for damaged goods.

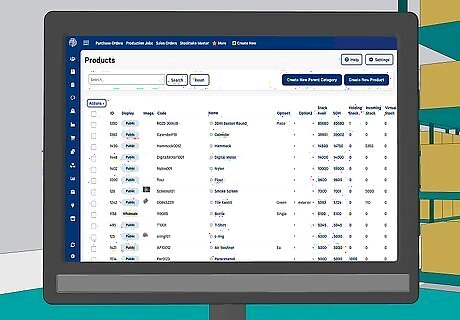

Organize the area with a thorough labeling or barcoding system. Knowing exactly what you have in your inventory (and how much) is an important part of running a warehouse, and that begins in the receiving area. Set up a space for inventory in your receiving area where goods can be recorded as received in your system, and use a warehouse management system (WMS) to help you keep exact track of your inventory. A proper cataloging system helps you manage warehouse operations and tells employees exactly where they need to be stored in the warehouse’s main storage area. Plus, cataloging perishable goods can help you determine and locate items that have reached their expiration date or have been recalled.

Set up put-away lanes to transport newly-received goods. Put-away lanes ensure the coast is clear for hand carts, forklifts, or whatever other machinery you use to bring goods from the receiving area to storage. Figure out how much space you’ll need to operate machinery safely and efficiently, then block off that space into clear, easy-to-navigate put-away lanes to ensure there’s space to maneuver and minimal traffic. For example, forklifts carrying a heavy load of products can be dangerous when they don’t have enough space to maneuver. If you plan on using a forklift, make sure it’ll have enough room in the receiving area.

Establishing a Shipping Area

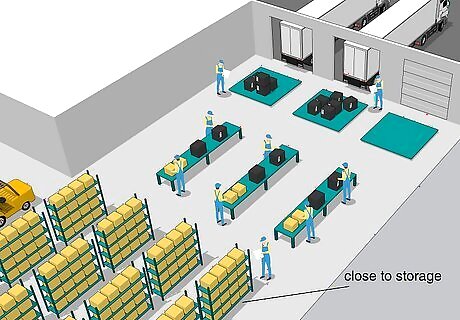

Ensure the shipping area is close to storage and picking locations. Keeping the shipping area close to storage can help streamline the process of picking, packing, and shipping items to customers. If possible, choose a space for your shipping area that is located conveniently close to storage—so long as that space is also big enough to accommodate the number of packing and shipping stations you’ll need and has enough docks for shipping vehicles. To make sure your shipping area is big enough, consider the type of products you ship and how much space you need to prepare them for shipping. For example, are your products big enough that you need space for a lot of larger boxes, or do you mostly ship smaller products that don’t take up a lot of room?

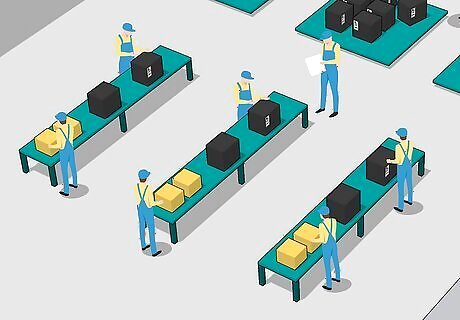

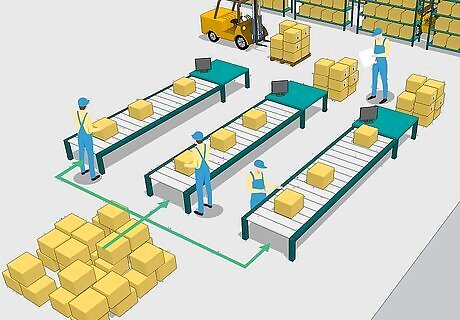

Set up packing stations in your new shipping area. Packaging tables give employees space to package, label, and prepare goods for shipment properly. It’s also where quality control typically takes place, and outgoing goods are inspected to prevent damage when they ship. Put together as many packing tables as you anticipate needing, and set aside space for them in your shipping area. Packing stations—also called “packing tables” and “shipping stations,” are very efficient because they provide a surface for packing and storage space for packing supplies in one place.

Stock packing stations with all the materials employees may need. First, list everything workers will likely need to pack and ship products from the warehouse. This includes equipment, automation tools, packing supplies, reference materials, and any protective gear that may be necessary. Then, rank those items by importance (from items used constantly to infrequently) and use those ranks to organize each packing station. For example, store items that are used most frequently in the most easily accessible spots (and items that are used infrequently towards the back of the packing station). Items to consider stocking at each packing station includes: Packing supplies like envelopes, bags, boxes, labels, markers, and pens Reference materials like instructions, signs, reference charts, and training materials Protective gear like gloves, jackets, or goggles A scanner and keyboard (if you have inventory and shipment management software)

Make space for order staging and organizing all shipments. Just as staging space is helpful in a receiving area, it can also help your shipping area run as effectively as possible. Set aside space next to the shipping area’s vehicle docks for staging so packages can be properly organized before they’re shipped to their final destinations. Decide how to organize packages in the staging area as well. For example, separating them into groups based on the carrier in charge of shipping (USPS, FedEx, UPS, and so on) helps ensure that all packages end up with the right carrier.

Optimizing the Warehouse Setup

Organize each part of the operation before setting it up. By carefully planning your shipping and receiving areas out on paper before ordering anything or setting up the warehouse, it’ll be easier to maximize your warehouse’s efficiency. First, figure out each procedure that needs to happen and what you’ll need to do that effectively. Then, design a map of your new warehouse layout, outlining spaces where each procedure can be completed. A thorough map can serve as a helpful tool to ensure that the procedures you outlined are completed in the correct order. Creating a map can also help you spot (and avoid) potential bottlenecks in the shipping and receiving areas. Throughout the mapping and setup process, keep an eye out for obstacles and workflow problems that may need to be addressed.

Create an ergonomic layout for both areas. Designing an ergonomic workspace essentially means organizing the layout to be as efficient as possible. It also means ensuring that workspaces are safe and secure for workers, which may mean having equipment (like lifts and conveyors) to do the heavy lifting. Elements to consider include: Reducing employee strain as much as possible by making sure all items are easily accessible. For example, storing the heaviest or most commonly-used packing materials at waist level rather than the floor might make sense, so employees don’t have to strain to pick anything up. Labeling different storage containers and items can also increase ergonomics, as workers can find what they need more easily. Even the location of different items can be ergonomic—for example, the heaviest or most popular products could be stored closest to the shipping area for easy access.

Schedule deliveries ahead of time for all shipments. Scheduling deliveries in advance and getting ASNs (advanced shipping notices) for them can help the receiving process run a lot smoother and potentially save money in the long run since delays can be costly. Knowing exactly when all of your shipments are arriving can help you have employees and equipment in place at the right time to unload and sort through it quickly. Scheduled deliveries are also crucial if you have a small warehouse with a shared shipping and receiving area. Without some organization, inbound shipments may accidentally coincide with outbound shipments, which can cause delays all around. Try scheduling deliveries only on certain days or times and do the same for shipping operations. That way, you’ll know for sure that there won’t be any conflicts.

Use inventory management software to automate processes. Inventory management software can help smooth the transition between the shipping and receiving areas and inventory storage, reducing the chances of miscounting the goods you have in stock. It keeps track of your inventory (and accounts for incoming shipments and outgoing deliveries), so you always have an accurate inventory count. For example: Inventory management programs like Cin7, Zoho Inventory, and Fishbowl can help track your warehouse’s inventory. Keeping spreadsheets of your warehouse’s inventory may help to make manual tracking more organized. If you prefer a barcode system, place unique barcode scanner stickers on the warehouse items to keep track of them and scan the barcode as items move through the warehouse. Alternatively, a radio-frequency identification (RFID) system uses tags that give off radio signals to count your inventory on a real-time basis.

Implement shipping software to manage shipped orders. Shipping software may help the warehouse manage outgoing shipments, print shipping details, and track shipments as they travel and get delivered to customers. Choose shipping software capable of creating labels for orders, collecting up-to-date shipping information, and working with any e-commerce platforms or retail websites you might also use. For example: Sendcloud can contact carriers, facilitate several different shipping options, and automate the return process to make it easier for everyone. It also allows each user to create their own custom workflow. ShipStation has the ability to track inventory between multiple warehouse locations, and it’ll find users the best rate for shipping labels. ShippingEasy can automate the entire shipping process from organizing packing and picking lists to tracking shipments. FedEx Ship Manager allows users to configure shipping methods as needed and create shipping activity reports.

Train your staff and communicate how each new process works. Before making any drastic changes to the warehouse’s shipping and receiving processes, train employees to ensure they have a strong understanding of the changes being implemented. Support open communication between management and employees throughout the process, and listen to employee feedback if they have any. Without training, mistakes are far more likely to occur often—which can cost money to fix each time. Effective training and communication ensure a smooth transition as you set up new shipping and receiving areas in the warehouse (and likely implement new technology as well).

Comments

0 comment