views

Measuring Screws with the Imperial System

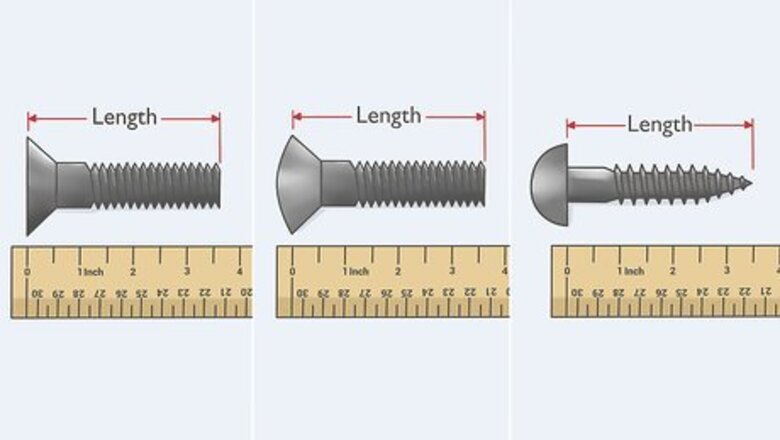

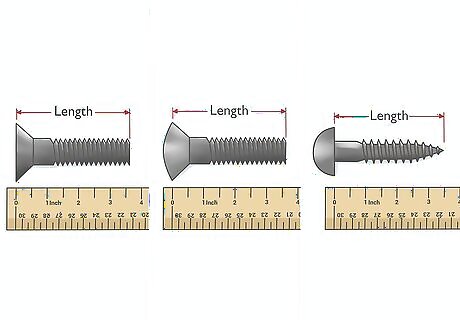

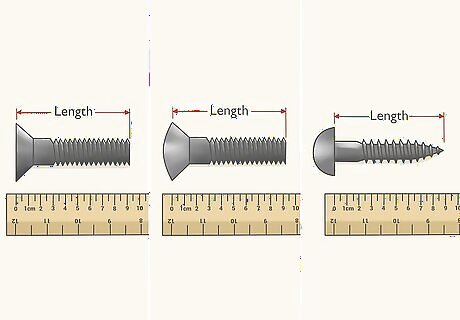

Measure in inches from the tip to where the screw head rests to get the length. Wherever the screw head would rest when it is fully embedded in something is where you start the measurement. Use a ruler or measuring tape to measure from here to the tip of the screw. For example, a countersunk screw with a flat head will rest flush with whatever it is embedded into, so start the measurement at the top of the screw head. For a countersunk screw with a rounded head, also called an oval countersunk, you start the measurement where the oval top and the countersunk half meet in the middle. In other words, where the oval top would rest on the surface. To get the length of round-headed screws that aren’t countersunk, start measuring from the flat underside of the screw head. You can also use a template to measure the length of the screws.

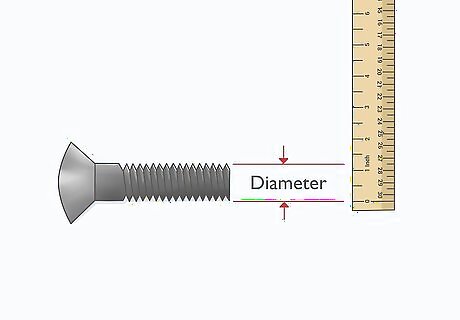

Measure the width of a thread in fractions of an inch to get the diameter. Use a ruler or measuring tape to measure from one side of a thread to the other using the nearest fraction of an inch. This diameter for screws in the imperial system is represented by either a gauge number or in fractions of an inch. A gauge number for screws in the imperial system corresponds to a certain fraction of an inch in diameter. To figure out the gauge number for a certain diameter, or vice versa, you have to look at a gauge guide to match up the "#" of the gauge with a fraction of an inch. You can find these guides online. For example, a #0 gauge screw is 1/16 of an inch in diameter, #1 is 5/64 of an inch, a #2 is 3/32 of an inch, and so on.

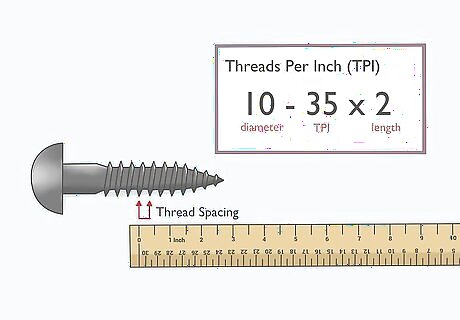

Count the number of threads in 1 inch to get the thread spacing value. Lay the screw next to a ruler or measuring tape and hold it steady. Count the number of threads in the space of an inch to get the thread spacing for screws in the imperial system.Tip: Screws sold with imperial system measurements on the packaging list the gauge first and the length next. They don’t usually list the threads per inch. For example, 10 x 2” means that the screw is a #10 gauge and is 2 inches long. If they include the thread count, it comes between the two numbers, like 10-35 x 2”. Thread counts in the imperial system generally range from 35-40 threads per inch. The thread spacing is also called the thread pitch.

Measuring Screws with the Metric System

Measure in mms from where the screw head sits to the tip to get the length. Start measuring from wherever the screw head would rest on the surface when it is fully screwed in. Use a measuring tape or ruler to measure from here to the tip of the screw. Take into account the type of screw head when you are measuring, because different screw heads rest differently on surfaces. For instance, a flat-headed countersunk screw will rest flush with a surface. Measure from the top of the flat head to the tip of the screw to get the length. Round-headed countersunk screws only sink part-way into a surface, so the rounded top will stick above the surface. Start measuring from the bottom of the rounded top. To measure any other types of round-headed screws that aren’t countersunk, measure from the flat underside of the screw head to the tip.

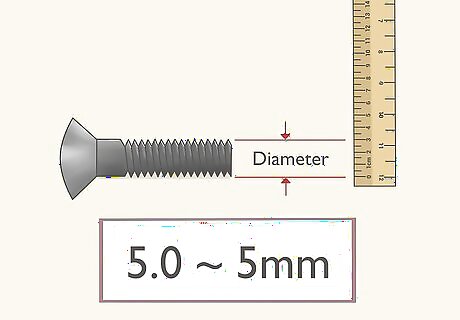

Measure the width of a thread in mms to get the diameter. Use a ruler or measuring tape to measure from one side of a thread to the other in mms. This is how the diameter is represented for screws in the metric system. If you’re buying screws with the measurements listed on the packaging in the metric system, then the first number represents the diameter. For example 5.0 means the screws have a diameter of 5 mm.

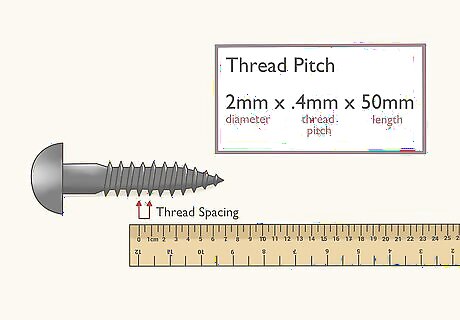

Measure the distance from one thread to the next in mms to get the pitch. Screws use pitch as a measurement in the metric system instead of thread spacing. Use a measuring tape or ruler to measure the distance from one thread to the next in mms to get this final measurement.Tip: Screws sold with metric system measurements on the packaging will list the diameter first and the length next. For example, a package of screws that says 5.0 x 60 means that the screws have a 5 mm diameter and are 60 mm long. The pitch of a screw is typically less than 1 mm, you would measure it as a decimal point of a mm. Most screws in the metric system have 1 pitch that corresponds to each diameter. For instance, 2 mm screws have a pitch of 0.4 mm.

Comments

0 comment