views

Measuring with a Carpenter Square

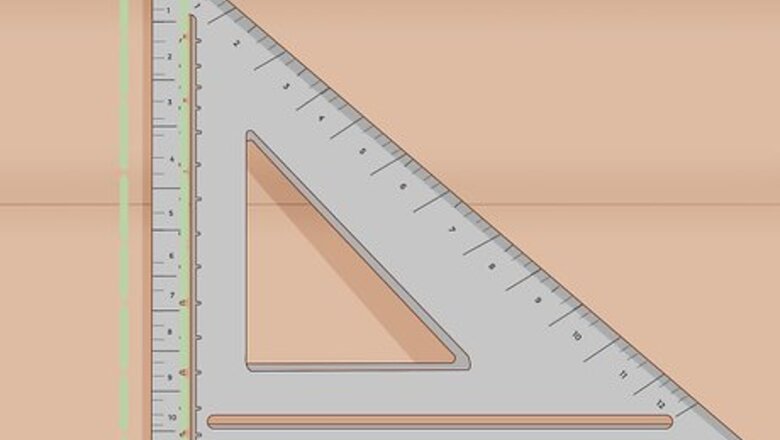

Use the ruled leg of the square to measure straight lines. The right-angle leg perpendicular to the base is designed to double as a standard ruler—simply use it the same way you would any other ruler. This will allow you to measure straight lines up to 7–12 inches (18–30 cm) in length, depending on the model you’re using. For measurements longer than 7–12 inches (18–30 cm), you’ll be better off reaching for a yardstick or tape measure.

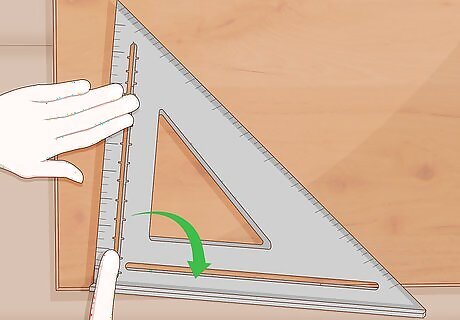

Measure angles by rotating the square from the labeled pivot point. The pivot point is the corner of the square where the two 90-degree legs meet. Press the fence against the edge of the board and use one finger to hold the pivot point steady. Carefully swing the tool outward along the board until you reach the desired angle on the leg opposite the pivot point. Mark the angle on the board using a pencil. A carpenter square can be used to measure and mark angles from 0 to 90 degrees, with accuracy up to about half a degree. Measuring and marking angles is crucial for making sure that roof rafters stand at the correct pitch, as well as cutting oddly-shaped accent pieces.

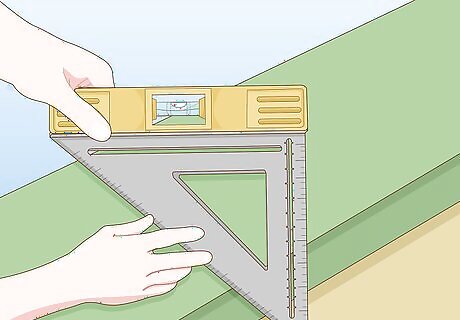

Determine roof pitch fast using a carpenter square and torpedo level. Align the pivot point with the outer edge of the roof where it meets the side of the structure, making sure the fence is facing up. Hold a torpedo level flat against the lip of the fence and adjust the height of the square until the bubble inside the level is centered. The point on the opposite leg of the square where it meets the roof’s surface will tell you the pitch. On most carpenter squares, the numbers indicating pitch can be found directly above those used to measure angles. Pitch is given as a single number, which is meant to be read in a rise-over-run format. If you get a measurement of 7, for example, it means the actual pitch of your roof is 7/12, or 7 inches (18 cm) of height (rise) for every 12 inches (30 cm) of length (run).

Check the precision of 90-degree cuts and joints. Hold the tool up to the squared edge to confirm whether the cuts or members on either side are exactly perpendicular to one another. If you discover that they’re not, trace along the right-angle legs of the square and use the markings to trim, shape, or re-set the components as needed. If one edge of a cut is off by a small margin, it may be easier to shave it down with a power planer than to try to cut away the excess material using a saw. Anytime you're working with materials that form a right angle to one another, it's a good idea to check them with your carpenter square along with your level.

Marking and Guiding Cuts

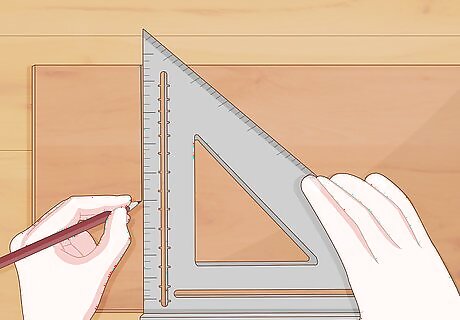

Mark straight cut lines on lumber easily using the fence. Hold the fence, or the leg with the elevated lip, flush against the long edge of your board. Then, run a pencil down the perpendicular leg of the square to draw a straight line across the board. Saw along this line to ensure that the ends of your boards have been cut to an exact 90-degree angle. Another advantage of the raised fence is that it holds the tool in place, making it less likely to shift and throw off the angle of your markings. This will likely be the feature of your carpenter square that you'll rely on most often, as the majority of the cuts used to shape building lumber are cross-cuts made at a 90-degree angle.Tip: Learning to quick-set the fence of your carpenter square can take the difficulty out of making repetitive square cuts for things like wall studs, floor joists, and stair stringers.

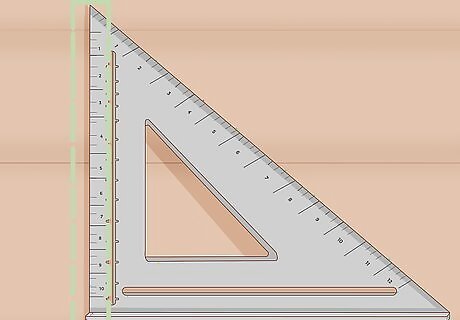

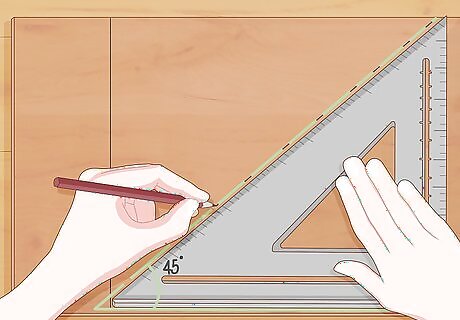

Scribe 45-degree lines with the diagonal leg of the square. The diagonal leg is the one that bisects that right angle formed by the fence and the perpendicular ruler leg. Line up the pointed end of the fence with the vertical edge of your material (or another straight marking). Trace along the tool’s diagonal leg to quickly mark a perfect 45-degree angle. If you just used your square to mark a 90-degree cut line, you’ll need to flip it over in order to draw an angled line from the same starting point. Being able to mark 45-degree cut lines quickly makes it much easier to fashion corner joints for things like door and window frames, cabinets, and furniture components.

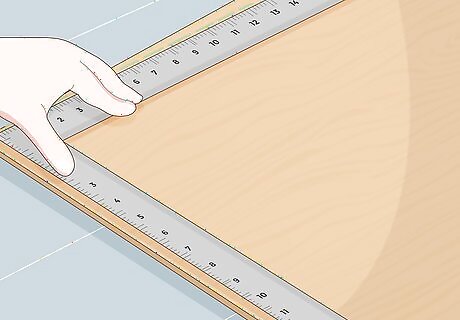

Use the line scriber slots to mark boards lengthwise for trimming. The ⁄4 in (0.64 cm) notches located on the interior of the triangle are used for marking lengthwise cuts on lumber. Set the fence against the edge of the board to frame it at 90 degrees and select the slot you want to use. Insert the tip of your pencil into the slot and slide the square down the board slowly to draw a line parallel to the board’s edge. This indicates where you need to cut along its length. Be sure to use the slot that most closely corresponds to the measurements of your planned cut, keeping in mind that the slots are precise up to ⁄4 in (0.64 cm). The line scriber feature can be useful when you need to rip boards to a thinner width or make notched cuts or jointed angle cuts.

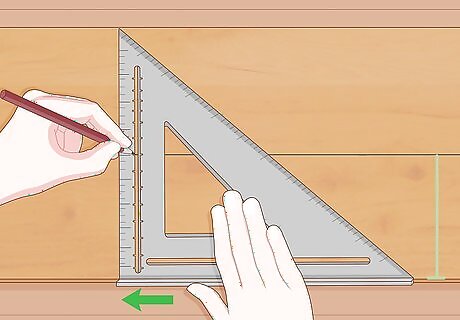

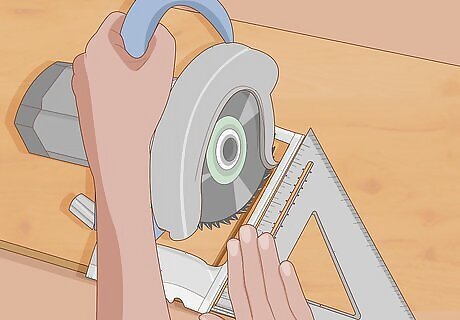

Set up the square as a saw guide for a circular saw. Position the tool with the fence resting against the edge of the board. Your guide leg should be running across the board at either a 90- or 45-degree angle, depending on the cut you need to make. Slide the saw plate flush against the outer edge of the square and push the saw along to make a neat cut from one end of the board to the other. Using your carpenter square as a saw guide makes it possible to get cleaner, more precise cuts than you could get by freehanding your saw. It also saves you the trouble of having to carry and configure a separate saw guide.Tip: Plastic squares tend to make safer saw guides than metal ones. Since they’re slightly thicker, there’s less chance of the saw blade accidentally riding up onto the square itself.

Comments

0 comment