views

Tensioning and Sealing Polyester Strapping

Wrap the strap around your load so the ends overlap on top. Place 1 end of the strap on top of the load and keep it in place by having someone hold it or setting something heavy on top of it. Slide the other end beneath the load, then pull it up and over. With polyester strapping, the end that is closest to your body should be on the bottom. Adjust the straps so they run down the center of the load to keep everything in place.

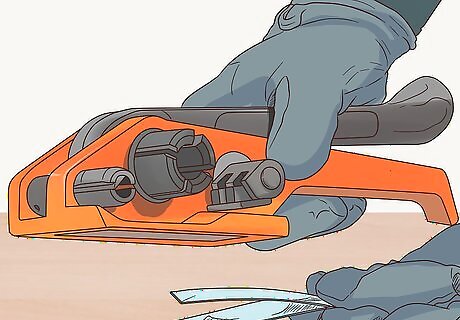

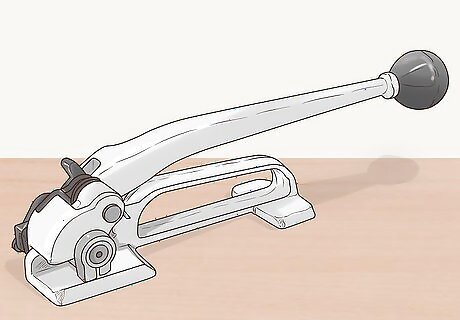

Squeeze the tension lever and the base handle on your tensioner. These pieces form the main handle on the tool. Squeezing them will lift up the gripper plate on the left side of the tool.

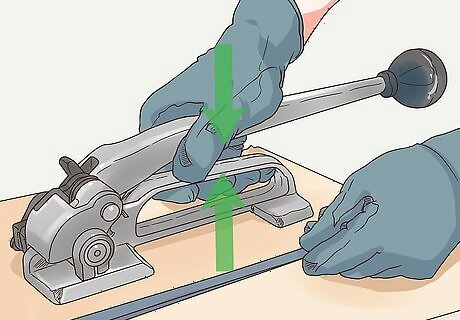

Place the bottom strap underneath the gripper plate and cutter wheel. Leave about 5 in (13 cm) of strapping in front so you have enough to secure later, and slide the strap up against the side of the tool. Once you have the bottom strapping in place, you can release the tension lever and base handle. The cutter wheel is the piece that looks like a knob on the tool’s front left side.

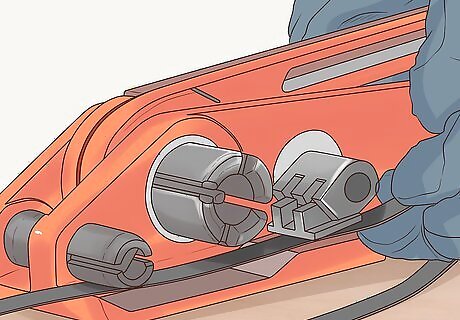

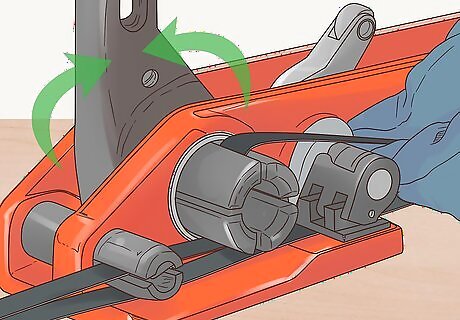

Lift the tension handle and thread the other end into the cutter wheel. Pushing the tension lever up will move the windlass (the middle ratcheting device on the left side of the tool) into place. The end of the strapping should go through the center line of the cutter wheel, then up through the center of the windlass. Once the strapping is in place, push the tension lever back and forth 2-3 times to tighten it up a bit and keep the strapping secure.

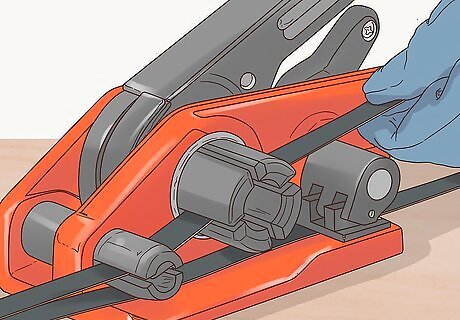

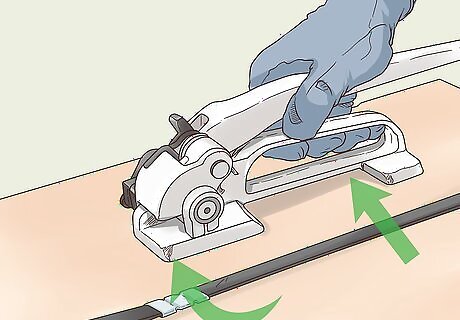

Move the tension lever back and forth to pull the strapping tight. Keep tightening until the strap is secure and taut around all sides of the load. The tensioner tool will ensure that you have a small amount of slack to apply the seals, so don’t worry about leaving any extra slack. Be careful not to over-tighten, which can damage the edges of the load and put too much strain on the strapping.

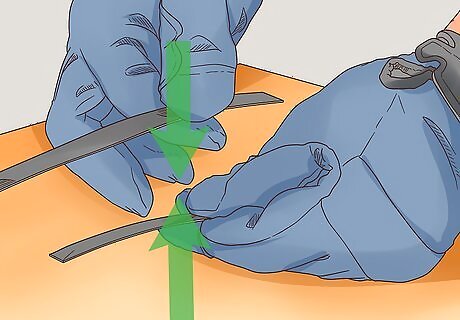

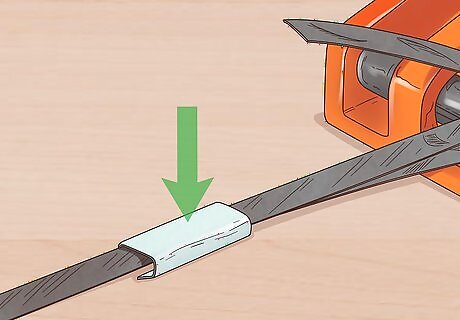

Place a gripper seal around the 2 layered straps in front of the tensioner. Set it down with the flat side on top and the 2 bent sides tucked around the strapping. Leave about 1 to 2 in (2.5 to 5.1 cm) of the bottom strap at the front of the seal.

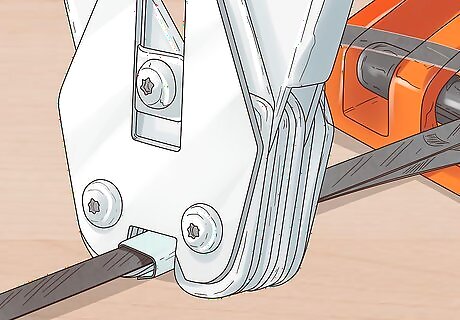

Use a sealer tool to clamp the seal shut. Completely open up the sealer tool and place it directly over the seal. Press hard, bringing the 2 handles together, to push the ends of the seal tightly around the strapping. Pull the handles apart and remove the sealing tool.

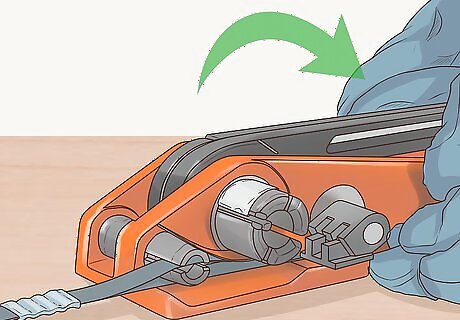

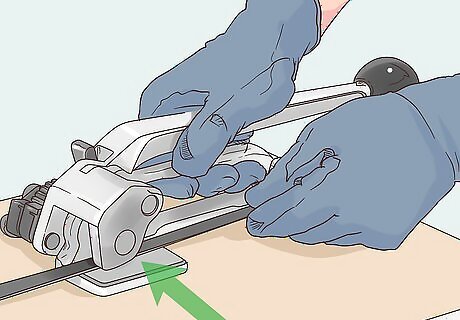

Squeeze the tensioner’s base handle and tension lever to cut the excess. Now that the straps are secured, go back to the tensioner tool and squeeze the 2 handles together again. Keep gripping the handles and slide the tensioning tool off to the right to remove it from the strapping. This will activate the cutter wheel, trimming the top layer of strapping to a neat length.

Tightening and Sealing Industrial Steel Strapping

Circle the strapping around your load and overlap the ends on top. Slide the steel strapping under the load, then bring up both ends around either side. Overlap the ends, making sure that the end that is closest to your body is on top. Adjust the strapping to center it around the load.

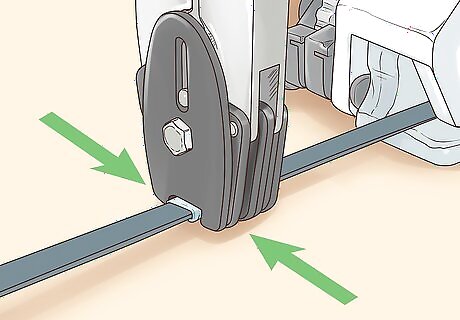

Squeeze the tensioner's tension lever and the base handle together. These pieces extend toward the back of the tool. Grip them both together to lift up the gripper on the front left side of the tool.

Place both layers of strapping under the gripper. Leave about 5 in (13 cm) of excess strap at the front of the tool so you have enough strapping to secure later. Release the tension lever to let the gripper fall and hold the straps in place.

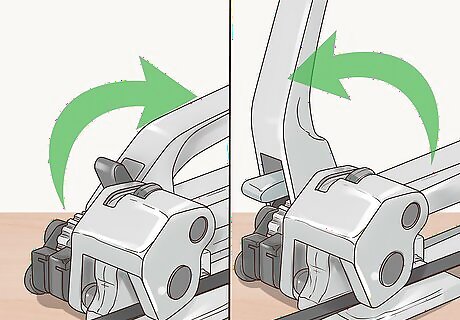

Move the tension lever back and forth to tighten the strapping. Keep ratcheting until you achieve the desired level of tension. The steel strapping should feel tight and secure around the load, but it should not be tight enough to cut into the edges. If the ratchet lever is in the upward position when you finish ratcheting, you’ll need to reposition it. Push the handle pull (located at the front of the tool) forward and gently bring the tension lever back down.

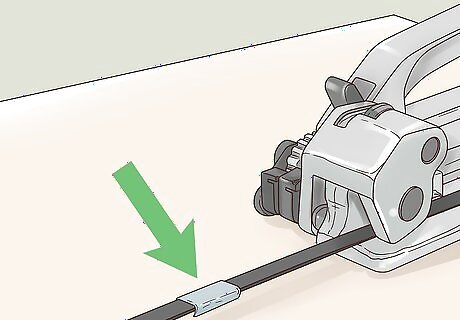

Place a seal over both layers of strapping in front of the tensioner. The seal should sit on the strapping, flat side facing up. Adjust it until its 2 bent sides wrap around the straps. Leave about 3 to 4 in (7.6 to 10.2 cm) of the top strap in front of the seal to help ensure that strap won’t slip through the seal.

Open up the sealing tool and press it around the seal. Spread the handles of the sealing tool’s completely apart and place the nose of the tool directly over the seal. Press the handles in to meet each other, clamping the seal into place. This will crimp down the top of the seal and press the bent sides upward. Spread the handles apart once again and remove the sealing tool.

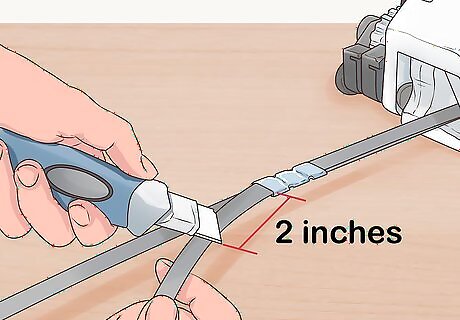

Cut the excess top strapping with a cutter tool. Lift the top strap up, away from the bottom strap, and use a cutter to trim off the excess. Watch out for flying pieces, since steel tends to snap off forcefully. Leave about 2 to 3 in (5.1 to 7.6 cm) of top strap, and throw away the trimmed end. Keeping a few inches of strap, rather than cutting right next to the seal, will help ensure it stays secure and taut.

Squeeze the tensioner’s tension lever and base handle to release it. This will lift the gripper and allow you to slide the tensioner tool off to the right. Now your straps will be secure and ready to hold the load in place!

Choosing and Positioning Your Strapping

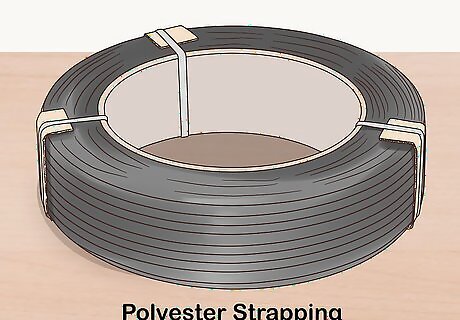

Use polyester strapping to hold together smaller loads and packages. Polyester strapping is lighter, cheaper, safer, and easier to use than steel. It also holds the highest retained tension of any plastic strapping, making it the perfect for medium to heavy-duty loads, such as pallets, or non-compressible loads, like shipments of bricks.

Select industrial steel strapping for large loads or construction work. This material works well on loads with sharp edges, such as steel or metal, and it functions best in extreme temperatures or indoor conditions, such as steel service centers, rail car applications, or boiler rooms. Choose from a variety of widths, then make sure your tools are meant to work with steel material. Use protective gear like thick work gloves and protective eyewear if you’re working with industrial steel strapping. This will help keep you safe if any steel strap goes flying as it’s cut.

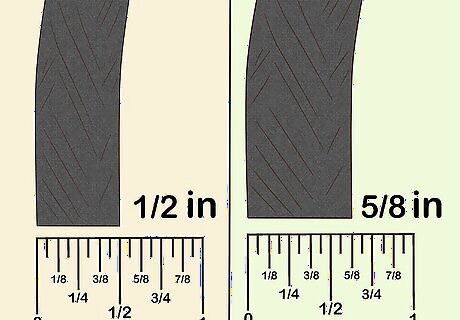

Choose from a variety of strap widths, based on your load size. The larger and heavier your load is, the wider your straps should be. Luckily, Uline offers several options for both polyester and steel. However, keep in mind that tools and seals are not interchangeable between sizes or materials, so make sure to use tools that match your strapping. Uline’s polyester strapping comes in 2 widths, ⁄2 in (1.3 cm) and ⁄8 in (1.6 cm). Their industrial steel strapping comes in a wider variety of sizes, including ⁄8 in (0.95 cm), ⁄2 in (1.3 cm), ⁄8 in (1.6 cm), and ⁄4 in (1.9 cm). If you already own strapping, measure its width to make sure the tools you order are compatible.

Comments

0 comment