views

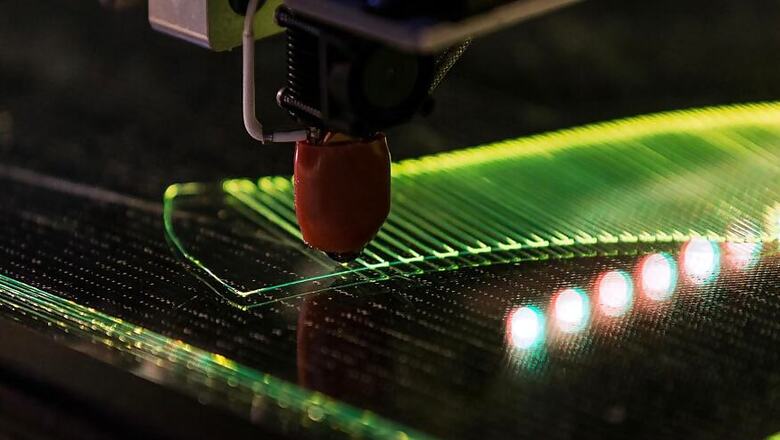

Nike has announced the use of an all-new technology for its footwear production and has termed it 'Flyprint'. As per Nike, Flyprint is the first 3D-printed textile upper in performance footwear. At its most basic level, Nike Flyprint uppers are produced through solid deposit modeling (SDM), a process whereby a TPU filament is unwound from a coil, melted and laid down in layers. However, it is antithetical to Nike to go a basic route. Instead, the Flyprint method allows designers to translate athlete data into new textile geometries. In this, it advances Nike’s efforts in digitally enabled textile development and adds to Nike's legacy of proprietary modification (or hacking) of machines — a heritage that includes Nike Hyperfuse, Flywire and Flyknit.

As per Nike, the process to develop the Flyprint uppers begins by capturing athlete data. That data is then computed (through computational design tools) to affirm the ideal composition of the material. Finally, that information is employed to produce the final textile. This operation confirms the versatility (outputs can be wholly unique to athlete or function) of Flyprint textile, as well as the increased pace of overall design time. Through performance printing, Nike claims to be capable of moving faster with unprecedented precision — prototyping is 16-times quicker than in any previous manufacturing method.

Also read: Symantec Announces Targeted Attack Analytics (TAA) to Protect ATP Customers From Cyber Attacks

Nike also highlights one interesting benefit of 3D textiles over traditional 2D fabrics. It states that an increased dynamism is made possible by adding an interconnection beyond a warp and weft. that means an advantage of Flyprint textiles comes in the fused nature of the material. For example, whereas in a knit or woven textile there is frictional resistance between the interlaced (warp and weft) yarns, in a printed textile, due to its fused intersections there is greater potential for precision-tuned containment. It is also lighter and more breathable than Nike's previously employed textiles.

In terms of design pace, the advantage of Flyprint method in traditional textiles is two-fold: Specific lines of the material can be adjusted locally while preserving the global construction, and rapid iteration means testing and revision cycle times are trimmed significantly. In short, Flyprint allows for a high-fidelity design with great athlete benefits in a short time.

Nike claims that the textile also works seamlessly with many other materials, most notably Flyknit yarns, to provide an optimal balance of fit and structure. In fact, Flyknit yarns can be engineered to thermally bond with the Flyprint textile, eliminating any need for glue or stitching.

With the Flyprint uppers, Nike aims to cater to the world’s fastest distance runners. And for that reason, its first articulation is in the Nike Zoom Vaporfly Elite Flyprint shoe. Created for Eluid Kipchoge, and driven by his feedback following last year’s Berlin Marathon and through a rapid-fire prototyping phase, the new upper improves the VaporFly Elite shoe and makes it 11g lighter than Kipchoge's original pair.

Watch: Nokia 6 (2018) Review: A Smooth Performer in a Striking New Design

Comments

0 comment