views

Preparing the Concrete Surface

Familiarize yourself with your concrete flooring. Concrete flooring that has been poured recently (in the last 10 years or so) is more likely to have been smoothed and troweled mechanically. What that means is that even though mechanically troweling the floors creates a nice, smooth top surface, it is too smooth for the acid stain to penetrate through. So, keep that troweling method in mind along with a few other conditions when figuring out if your concrete surface would be a good surface for acid staining: For concrete surfaces that are older, power-washed, or have been profiled using a machine, the surface of the concrete has to be virtually pristine before adding an acid stain. That means there should be no areas of damage revealing exposed underlying concrete or sand granules. If there are areas that are damaged, those areas are going to absorb the acid stain abnormally, and may cause areas of inconsistent coloring. The concrete slab should be free from waterproofing agents, or muriatic acid. The acid stain reaction cannot occur on surfaces treated with these products. You can usually tell if a concrete surface has a layer of waterproofing by performing a water test. All you do is pour water onto the concrete surface. If the water beads up and does not absorb into the concrete, it’s treated with a waterproofing agent. If the water sinks into the concrete, your concrete should readily absorb acid stain.

Familiarize yourself with the factors that can affect your acid staining. The current condition of the concrete is one of the biggest factors to consider when acid staining is the current condition of the concrete. An initial questions to ask yourself before staining is, “What’s on the floor now?” Depending on the answer, your concrete surface could be ready for cleaning and a direct acid stain (meaning applying the acid stain directly onto the concrete surface in its current condition), or more floor prep (and possibly a surface modification) before the acid stain application. Some other factors that can affect your acid staining include different flooring material covering the concrete surface, how the concrete surface was troweled, if the concrete has ever been patched or repaired, and if there was carpeting, if the carpet underpad was glued onto the concrete. The ideal candidates for direct acid staining are usually new construction projects (where nothing has been applied to the concrete floor and it has been kept clean), and exterior projects. Remodels are harder, as any imperfections left behind from the previous floor covering (tile, linoleum, wood, carpet, laminate, etc.) will show up to some degree in the final acid stained concrete floor. Remodels mostly require more prep work before the acid stain application.

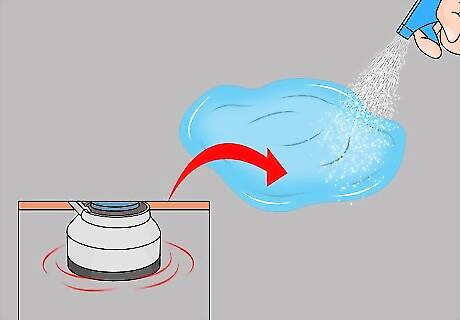

Perform a water test to check for a sealer. Sprinkle or spray water in several places on the concrete surface. If the water beads and the color of the concrete doesn’t change in the areas you sprayed, then a barrier (usually a sealer) is present on the concrete surface, and must be removed during the floor prep process. This barrier must be removed because it will prevent the acid stain from even penetrating the concrete surface. You can remove this barrier by sanding the top layer of the concrete, or applying a micro finish overlay on top of your concrete. These barrier removal steps may also require a combination of chemical cleansers to dissolve any additions made to the concrete's surface.

Modify your concrete surface if necessary. Not all concrete surfaces will require this step, but for surfaces that have a chemical barrier on top of the concrete, are too smooth because they were machine troweled, or contain excessive contaminants from previous flooring, may all need some surface modifications. This is when sanding or a micro finish overlay may be required. Sanding the floor with a high-speed buffer and an 80-grit sanding pad provides a roughened concrete surface that helps ensure maximum adhesion of the acid stain. Sanding also helps to remove superficial contaminants like paint or surfaces stains, while removing the top layer of a sealer. After sanding, the entire floor will feel like sandpaper and the surface debris will all be sanded away. A micro finish overlay is a thin, smooth coat of concrete that resurfaces the floor to cover up defects left behind from previous flooring. This is because any residue from your previous flooring (carpeting glue, nail holes, tile adhesive outlines) can leave a “ghost image” that shows up later in acid staining process. A micro finish overlay is a little more expensive than a direct acid stain, but the resurfacing virtually eliminates all imperfections on the floor, and creates an even, covering over the original concrete that ends up looking a lot like leather. This step could get tricky for someone doing this project by themselves, and may require the professional assistance.

Choose your concrete cleaner. Once you have made your concrete surface ready for proper acid staining absorption, you need to clean the concrete surface. There are a few different concrete cleaners that can rid your concrete surface of impurities in their own way. Knowing the differences between these cleaners will allow you to clean your concrete surface with a cleaner best suited for your surface’s deposits.

Consider using a pH-neutral cleaner. A pH cleanser is mild in nature, and are normally used for cleaning indoor concrete surfaces that are already sealed. These pH cleaners can also be used on unsealed exterior or interior concrete that only requires gentle, non-irritating cleaning.

Consider using an acidic cleaner. These are the most popular types of concrete cleaners. Acidic cleaners are mainly used to get rid of staining, dirt contamination, and other contaminants that can be broken down by its acidic properties. Acidic stains come in ready-to-use applications or more concentrated solutions, and they are applied right onto any area that is affected by contamination. Acidic cleaners sometimes need to be scrubbed into the contaminated areas, and may even require more than one application.

Consider using alkaline cleaners. Alkaline cleaners are mostly used to get rid of tough stains like oil, grease, or other hard to remove hydrocarbon-based stains. These cleansers are very effective in breaking down oily and greasy contaminates due to the high alkalinity. Alkaline cleansers reap the best results when the cleanser is scrubbed into the concrete stains. A big mistake people make when using this cleanser is not giving it enough time to work its magic and remove the stain. Depending on how bad the oil stain is and how far it has seeped into the concrete, you made need to apply this cleanser many times to fully eradicate the stain. Each application will require a sitting time of approximately 3 hours.

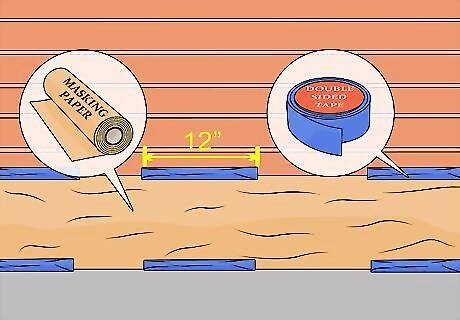

Mask the walls. Protect your walls from getting acids stain on the bottoms and edges by covering them with masking paper. Cover all exposed walls by pulling the masking paper tightly across the wall (covering the areas closest to the floor), and securing the back of the paper to with wall with double sided tape (a piece of tape taped onto itself, sticky side out, making a loop). Spread the tape out about every 12 inches to ensure the masking paper is applied evenly.

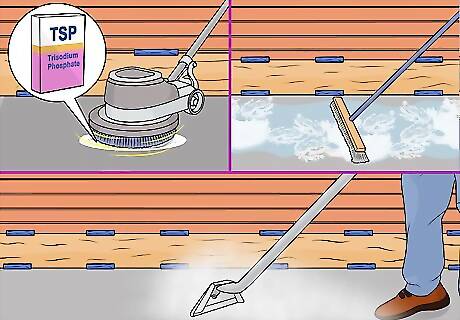

Clean the concrete surface thoroughly. For general-purpose cleaning, sweep the floor to pick up any superficial dirt, and then scrub the floor thoroughly with trisodium phosphate (TSP). To scrub the TSP, consider using a machine powered floor scrubber with a heavy duty nylo-grit scrubber designed for aggressive concrete cleaning. Then use an industrial wet vacuum to remove all water and debris.

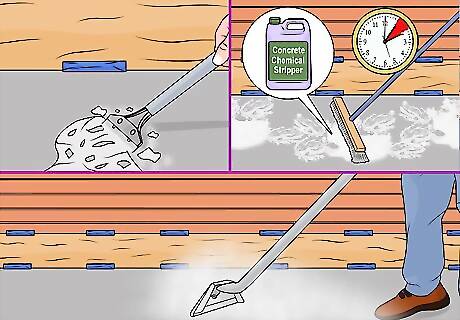

Remove caulk and mastic residue. Mastic and caulking compounds are incredibly difficult materials to remove from concrete. Use a putty knife or floor scraper to scrape and remove as much of the sticky substances as possible. Then use a chemical concrete chemical stripper to remove whatever leftover residue remains. Apply the cleaning agent to the concrete surface, and allow it to sit for approximately 1 hour, so it has time to soak into the concrete. Then, thoroughly rinse the surface with water, and clean up the water and debris with a wet vacuum. You can find a concrete chemical stripper at any home improvement store. Also consider using a poultice to remove mastic substances. To make a poultice, mix a fly ash or hydrated lime with denatured alcohol. This mixture makes a paste that can be added to contaminated areas. After you apply the poultice paste to the areas that have mastic residue, wait for the poultice to dry (close to an hour, maybe more depending on how thick you applied the paste), and then scrape off the now crumbling mastic debris with a putty scraper or stiff brush.

Do a final cleaning of the floor. It's very important to clean the floor one more time after using all the chemical cleaners, to remove any and all remaining residue. Scrub the concrete surface one more time with TSP, and then follow up once more with a thorough washing and rinsing with clean water. After the final rinsing of the concrete, again, use a wet vacuum to pick up all the remaining water and leftover particles.

Staining The Concrete

Put on your safety equipment. Remember to use goggles, gloves and a ventilation mask while working with concrete acid stain. A activated charcoal respirator may be your best defense against fumes, especially with staining concrete in areas of poor ventilation, like basements. However, even basements should be has well ventilated as possible, using fans and open windows to circulate and draw in fresh air. Also consider wearing a long sleeve shirt and pants, combined with knee guards, in case you have to get on your hands and knees.

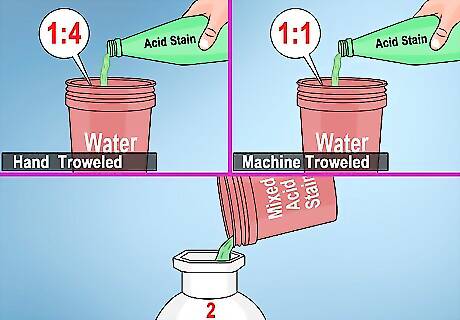

Mix the acid stain. The acid stain mixture contains strong chemicals and fumes, so be sure to mix the stain somewhere outside, or in an area that has adequate ventilation. Pour the mixed acid stain into a plastic pump. Usually a two-gallon pump is sufficient, but be sure that it is made completely of plastic. It is important that the applicator or spray wand is also made of plastic rather than metal, because hydrochloric acid (one of the key ingredients in the acid stain), corrodes metal very easily. For floors that have been troweled and smoothed out by hand, dilute the acid stain with a 1:4 ratio of 1 part acid stain to 4 parts water. For floors that have been troweled by a machine, (which are mostly industrial or commercial flooring), the acid stain mixture will be more concentrated, with a 1:1 ratio of one part acid stain to one part water. When mixing and diluting the acid stain, you need to pour the acid into the water rather than pouring the water into the acid. This is because acids release a lot of heat when mixed with water. The water is added to the acid so you can start with a very diluted and weak acid mixture instead of adding water to the acid, and starting with a very strong acid mixture.

Test a small area of concrete. Always apply a test sample of stain to a small, inconspicuous area of the concrete to be treated. Because so many variables can affect the final color, that’s the only way to get an accurate preview of the finished look, and even then, the final outcome might look a bit different.

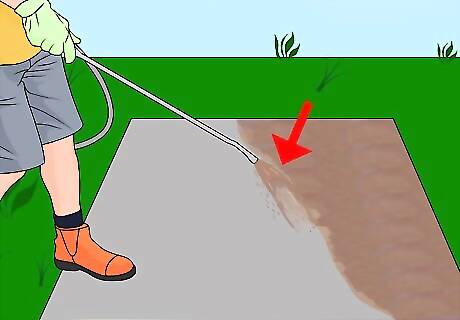

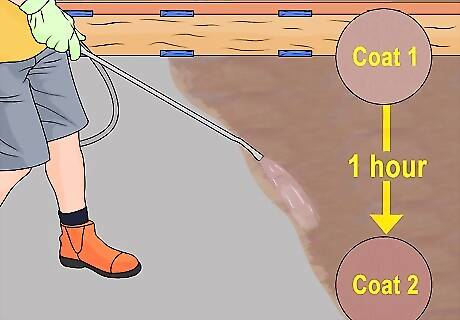

Apply the acid stain to the concrete. Normally, the most effective and efficient way to apply acid stain to concrete is to use a sprayer. A sprayer helps to evenly coat the concrete surface while providing quick and complete coverage. It also helps to avoid creating puddles with the stain by spraying a large area at a time rather than smaller, more concentrated areas. The spraying container you use must to be made out of plastic, and have plastic parts (like the spraying tip). That’s because the hydrochloric acid in the acid stain is highly corrosive to metal, and can cause a dangerous acidic reaction while ruining your sprayer. Start your spraying in a rear corner of the room so you can spray the entire floor and walk out of the area without walking on top the acid. Spray the acid stain with the spraying wand about a foot and a half above the ground. Consider using figure 8 patterns to spray the acid stain randomly but evenly, to thoroughly coat the floor with the stain. When you apply the acid stain, the lime deposits in the concrete are what react with the acid, giving the flooring its different coloring. Let the first coat of acid completely dry (about an hour) before adding a second coat. You can stop applying acid after the second coat, or keep adding coats until you get the coloring you want. Be very careful when walking around the stained area. Footprints from stepping in acid stain and then walking on unstained concrete can leave “burn” marks in the concrete (basically acid stains of shoe prints). Acid resistant spiked shoes (similar to soccer or golf shoes, and made with acid resistant stainless steel), are really helpful for walking around during the acid staining process, because they leave minimal shoe markings on the floor. The spikes cover less area, making foot prints a lot less visible and easier to blend into the rest of the acid stain. Don't expect color consistency or perfection. Variations are inherent in the staining process.

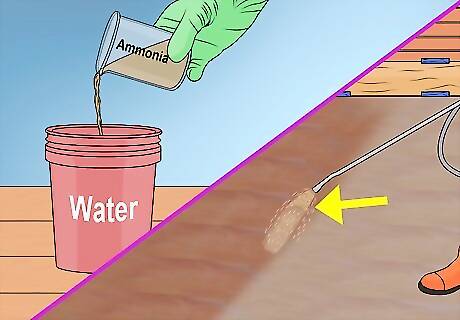

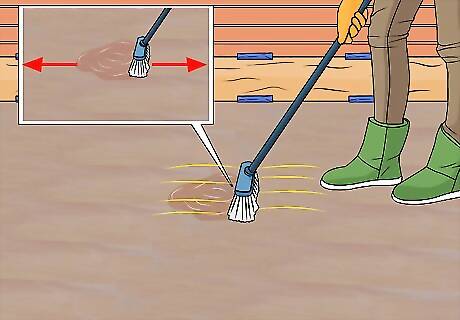

Neutralize the applied stain. Wait until the chemical reaction of the acid stain is complete before you neutralize the staining. It generally takes a minimum of 3 to 4 hours after applying the acid stain for the full chemical reaction to take place. The neutralizing solution is a 4:1 ratio mixture of four parts water and one part ammonia. Spray this neutralizing mixture on the floor using a plastic pump sprayer like you did with the acid stain. After spraying the neutralizing solution, the floor will look like you are washing away the acid stain. Don't be alarmed, this is just the stain residue. The acid will have already reacted with the concrete. To scrub and properly neutralize the floor, use a broom that has stiff bristles (perhaps a broom with medium bristles - not too soft not too hard), or a slow-speed floor scrubber, and work the neutralizing solution across the entire concrete surface. You may need to perform many scrubbings to fully neutralizer the surface, especially if the acid stain used was a darker color.

Clean up the floor. Use a clean mop or a big push brush with soft bristles to wash the floor and scrub off any extra water and neutralizing agent. Then, use a shop vacuum to immediately suck up the residue from the floor before it has time to dry. After you vacuum up the water and residue with the shop vacuum, you should have a general idea of how the acid coloring will look on the concrete. Allow the floor to dry completely before you add on your sealer. At this point in the process, there’s not really a way to make touch ups to the floor. You will have an idea of how the finished floor will look, but until you add the sealer, the final product is still unpredictable. If there is any remaining amount of moisture on the floor before the solvent-based sealer is applied, the concrete will have a cloudy haze covering the entire floor. This haze can only be removed by stripping the sealer and reapplying. One of the easiest ways to check if the floor is moist is to use blue painters tape. Try to stick the tape to the floor. If the tape sticks, the floor is thoroughly dried. If not, the floor is still moist and needs more time to dry.

Know what kind of finish you want on your concrete. Apply a sealer to seal in the acid stain and add a layer of protection to your concrete flooring. Adding a sealer can also help boost the appearance of the acid stain coloring. For interior acid staining projects, film-forming sealers (sealers that provide a protective top coat on the concrete surface) are the kind most often used. However, there are several different types of these sealers, and each type has its own benefits and restrictions.

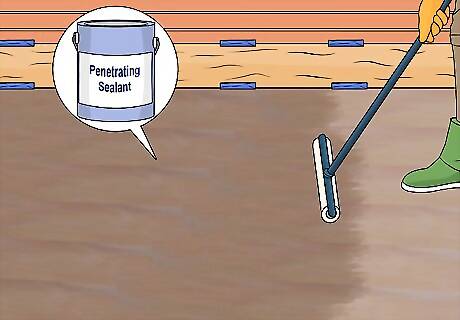

Consider using a penetrating sealer. These sealers include silanes, siloxanes, and silicates. These are mostly used on outdoor concrete surfaces because they provide excellent protection from harsh, outdoor weather conditions.

Consider using an acrylic sealer. Acrylic sealers are used on both indoor and outdoor concrete surfaces. These types of sealers help bring out color from stained surfaces, and usually dry within an hour after application. They are available in both solvent-based and water-based formulas, but the solvent-based acrylics generally heighten color appearance better than their water-based counterparts. When acrylic sealers are used on indoor surfaces, they usually need many coats of wax (to act as a barrier), preventing scuffs from shoes and floor traffic. Acrylics normally wear faster than polyurethanes and epoxies.

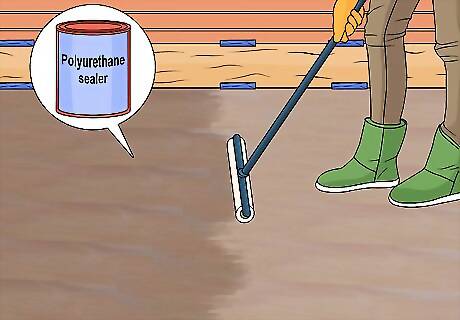

Consider using a polyurethane sealer. Polyurethane sealers are used mostly in places like restaurants or entryways because of their durable resistance to things like shoe markings and stains. These sealers come in a wide variety of shine levels, and have a clear finish once they dry.

Consider using an epoxy sealer. Epoxies (which normally consist of a mixture of two highly protective compounds) form an extremely defensive coating on concrete surfaces. Since epoxies tend to yellow when exposed to UV rays, they tend to be confined to indoor concrete surfaces. Epoxies give a long lasting, durable finish while also being extremely water resistant. However, because of their nonporous nature, epoxies can sometimes trap water and moisture within the concrete.

Seal the floor. Rather than applying one heavy coat of sealer, apply many thin coats. Sealers can be applied with either an applicator sprayer, or paint roller, but using a spray tends to be the easiest application method. If you use a sprayer, avoid spraying too much in one area and creating small pools of sealer. If you used a paint roller, push the sealer on the floor rather than pulling it. Pulling the paint roller will result in streaks across the concrete. Allow adequate drying time (normally about 1 hour) before adding addition coats of sealer. However, a second coat of the sealer must be applied within four hours of applying the first coat. After four hours of sitting time, the first coat of sealer is too hard for the second coat to bond properly. If you use a sprayer to apply your sealer, consider using a cone-shaped spray tip rather than a fan-shaped spray tip. Allow a minimum of 4 hours before subjecting the surface to foot traffic. Within 3-4 days, the sealer will be fully dried and ready for everyday wear and tear.

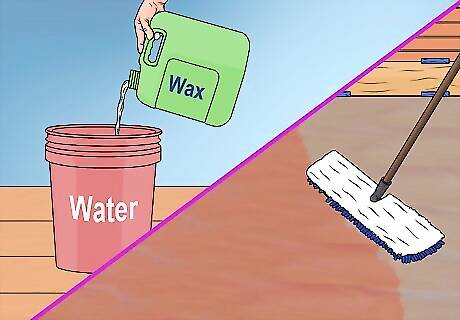

Wax the concrete surface. To protect the sealant, it’s best to apply a wax finish on top of the concrete flooring. The easier way to apply wax to the acid stained floor is using a mop and a mop bucket. Pour the wax into a mop bucket, wring out the mop so it's not dripping with wax, and then apply the wax on the concrete in figure 8 patterns. After you apply the first coat of wax and wait about a half hour for it to dry, you can take down all the parchment paper you used to protect the bottoms of the walls. If the masking paper pieces fall on a concrete floor that has just been sealed, hasn't had time to dry, and hasn't been waxed yet, they can stick to the floor practically like glue. However, if the pieces of parchment paper have the chance to fall on the wax coating, they can be picked up right away. Normally within an hour of applying the final wax coating, you should be able to walk on the concrete surface. However, you should wait at least 24 hours before you move any furniture onto the freshly waxed surface. The longer the wax gets to settle on the floor, the harder and more protective it becomes. Supplementary wax coats are usually applied every three to six months to ensure the finish continues to look its best.

Comments

0 comment