views

Professionally Bending Rebar

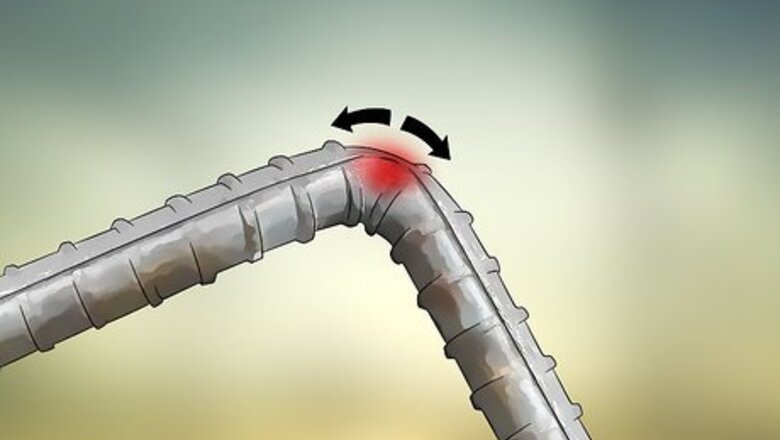

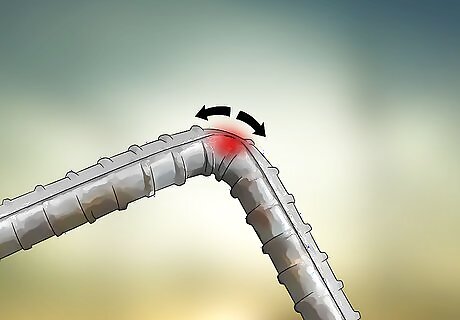

Understand the structural issues possible with manually-bent rebar and know how to avoid them. When you bend metal, you naturally weaken it. When done correctly, however, you can minimize damage and still get the shape you need to complete the project. Keep the following in mind as you work: Always note the grade and size of the bar you're bending, checking against the equipment you're using to ensure it works. Check with your project engineer to ensure your bends meet the minimal internal bend diameter. If you don't know what this is for your project, wait until you do. Never re-bend rebar. Once you've bent it, it's finished. Continually working it will significantly lower its strength.

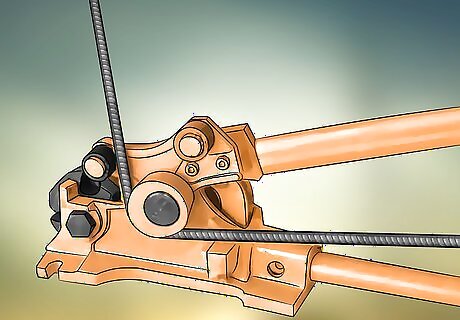

Look into a manual bender for a cheap, portable rebar bending solution. These devices usually clamp the rebar down, allowing you to pull down on the free end to bend it. The bar is set on a cast-iron die, allowing you to easily bend it to your desired curve. However, they are slow, only bending one piece at once, and they usually only bend in 90-degree increments, meaning you must guess to get other angles. However, they are also relatively cheap. Cost from $200-500. Can only handle lower-grade steel and sizes.

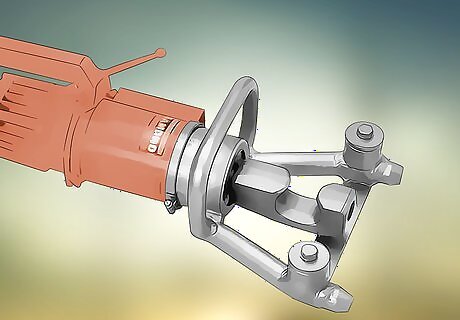

Consider getting a power bender to make perfect hooks and bends on the go. These electric or gasoline-powered motors are essential if you need a lot of bends quickly, all to a standardized length. Many come with cutters, too, allowing you to sheer overly long bars. Though expensive, and heavy, they are essential for big construction crews who need precise, frequent rebar adjustments. To use it, simply turn it on, set your desired angle and length, and feed in the rebar. Cost from $3,000-5,000. Can handle any grade steel, or any size.

Recoat any galvanized or epoxy coated rebar after bending. The process of molding or shaping the rebar often causes coatings to chip and flake off. As long as your remember to check and touch up the areas that you've bent, however, you should not have much of an issue.

Bending Without Professional Equipment

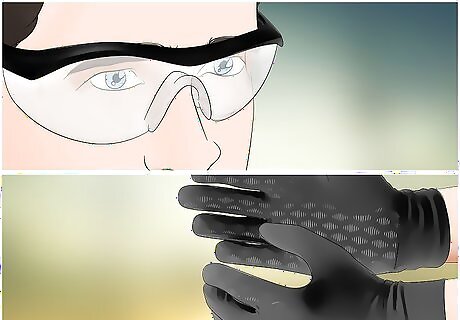

Wear personal, protective equipment. One of the first steps for trying to bend rebar is to use appropriate safety gear. You must have eye goggles and glove, at the bare minimum. It may also help to wear long sleeves and pants, protecting your arms and legs. Work in an open, free space where there are not a lot of people. Cut rebar can be jagged. Any exposed ends should be covered by OSHA-approved rebar caps.

Choose a piece of rebar that can be reasonably bent by hand. Some experts suggest choosing thinner rebar, such as a 1/4-inch design, for smaller projects where users will need to bend this steel into different kinds of shapes. If you need anything larger, however, you should consider trying professional and mechanical methods, as bending by hand will be difficult and dangerous. The type of rebar needed is not purely up to choice -- there are important structural codes that you need to follow when constructing.

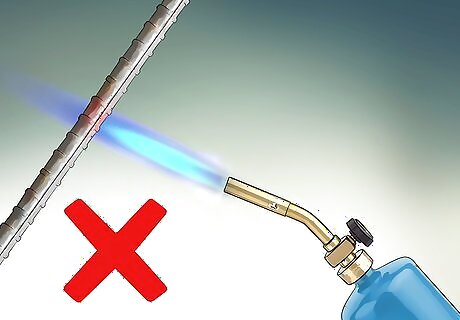

Do not heat rebar in order to bend. The issue of whether heating rebar can help individuals to bend it is under a significant amount of debate. Some experts and experienced steelworkers maintain that heating rebar is appropriate, and can help individuals to bend it effectively. Others point out dangers and consequences of heating the steel, saying that this is not a good general practice for changing the shape of a piece of rebar. At the end of the day, follow this simple guideline: if it is "non-weldable rebar," then don't heat it up at all. If is isn't, go ahead if you think it will help.

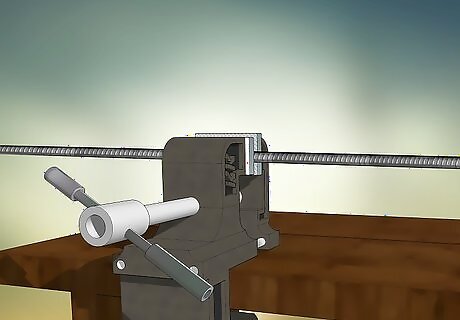

Put the rebar into a vise, lining up your future bend with the end of the jaws. In order to bend rebar, you will need to hold one side of it in place, then pull down on the opposite end to bend it. As the vise holds the rebar in place, it bends right where the vise stops and the "free" section of the bar begins. Make sure your vice is well-anchored to your work bench. Your bend should be right at the end of the vise jaws.

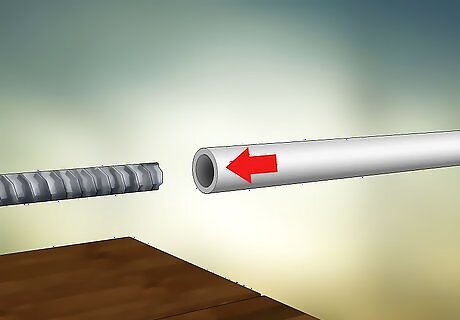

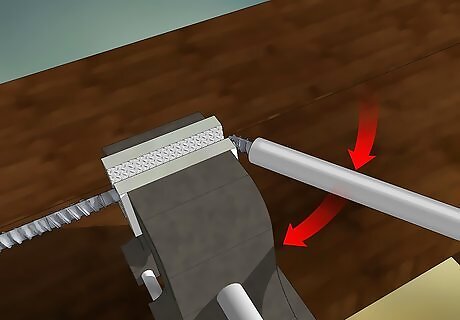

Place a steel pipe around the free end of the rebar. This makes it easier to hold and bend. The longer this pipe, as well, the more leverage you can get on the rebar, making it easier to bend. The longer your lever, or the free area outside of the vice, the less power you need to make your bend.

Put slow, even pressure on the bar to bend it. Slowly and carefully press down on the steel pipe covering your rebar until you get your desired bend. For precise bends, you'll likely need a mold. You can cut and carve wood blocks, for example, and bend them the rebar around that. For even more precise bends or thicker rebar, you will need to move on to professional equipment, however. These machines come with dies that you bend the bar on top of to get the perfect angle.

Never hit or smack a piece of rebar to bend it. The sudden impact of a sledgehammer, for example, leaves you little control over the final shape. What's more, over bending damages the steel surface and can cause the bar to break of fail down the line.

Comments

0 comment