views

Framing the Opening

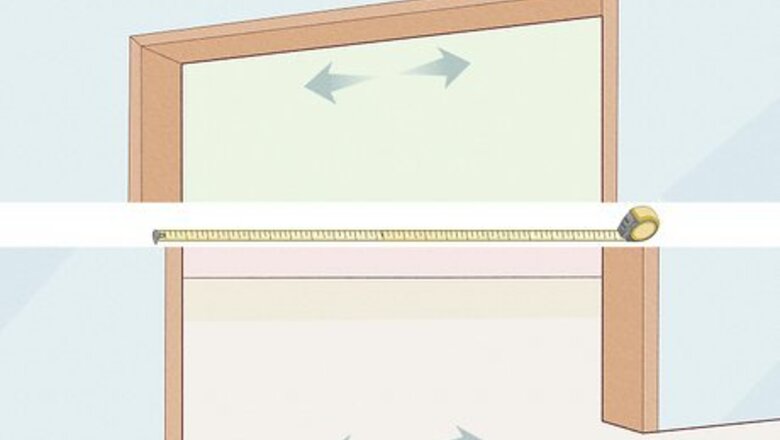

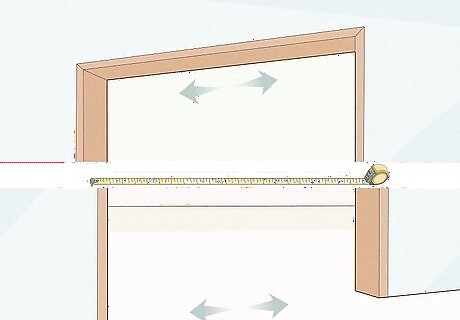

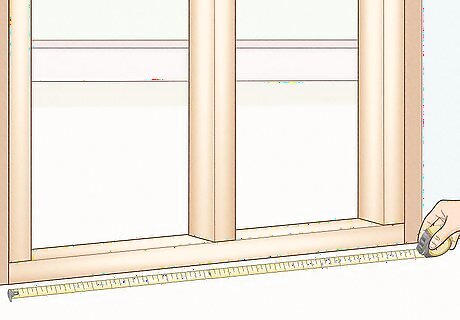

Measure the top and bottom spaces of the opening. Use a tape measure or ruler to get an exact measurement. Check the width of the top and bottom of the door opening and write those measurements down so you don’t forget. Standard doors are usually 32–36 in (81–91 cm) wide. Your door will probably be around that, but be sure to take an exact measurement.

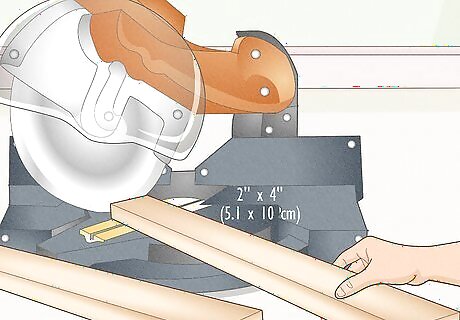

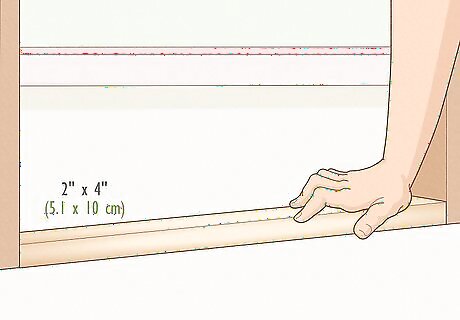

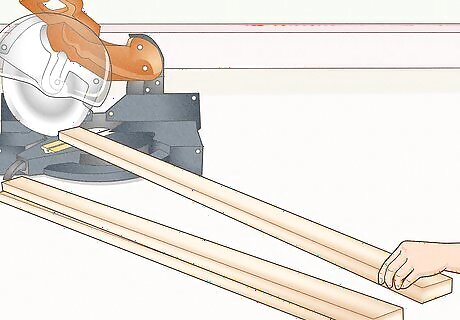

Cut two 2 in (5.1 cm) x 4 in (10 cm) boards to fit that space. Measure the wood and find the length that matches the width of the door space. Mark a straight line at each spot with a pencil and straightedge. Then use a circular saw or table saw to cut along those lines and get two wood boards that will fit in the space. Always wear gloves and goggles while you’re using a saw. Keep your fingers far away from the blade while it’s on. Be sure to use a straightedge or ruler to make a straight line on the wood. Otherwise your cut might be crooked. Use a 2 in × 6 in (5.1 cm × 15.2 cm) board if the wall is 6 in (15 cm) thick.

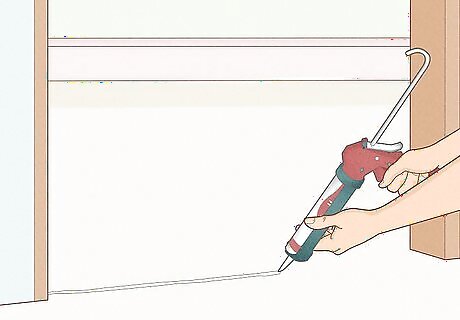

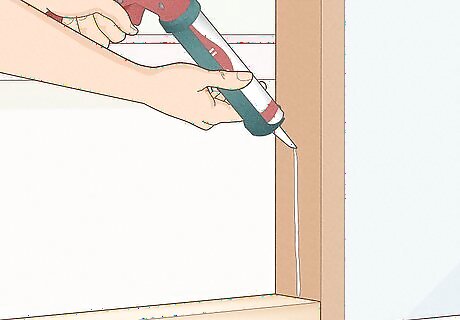

Place a bead of caulk along the top and bottom edges. Hold the caulk gun at the bottom corner of the door frame, right in the middle. Squeeze the trigger to release the caulk and move the gun across the floor slowly to run a bead across the whole opening. Do the same on the top when you’re finished. This provides a bit of extra insulation for the space. Latex caulk is best for this because it expands and fills gaps well. You don't need silicone caulk unless you're making a water-tight seal, like for a bathroom. This step is more important if you’re sealing an outside-facing door. If it’s an inside doorway, then the extra insulation isn’t as important. The caulk dries in about 30 minutes, so place the wood boards right after you place it. Caulk is easy to remove while it’s still wet. If you get some in a spot you didn’t want it, just scrape it off with a putty knife and rub the spot with a wet towel.

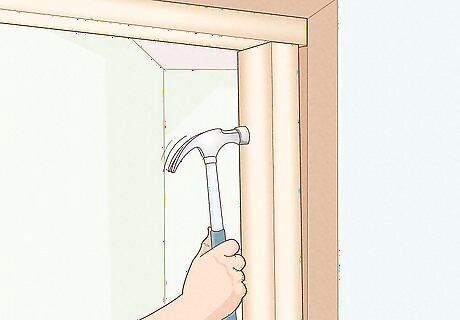

Press each 2 in (5.1 cm) x 4 in (10 cm) board into the caulk. Slide one 2 in (5.1 cm) x 4 in (10 cm) into the door space at the bottom. Hold it so it’s flush with the opening on either side, then press it down into the caulk. Do the same for the top. If the wood isn’t totally even with the space, you can still slide it back and forth a bit to fix it. You might need to tap the wood with a hammer to fit it into place. This is normal.

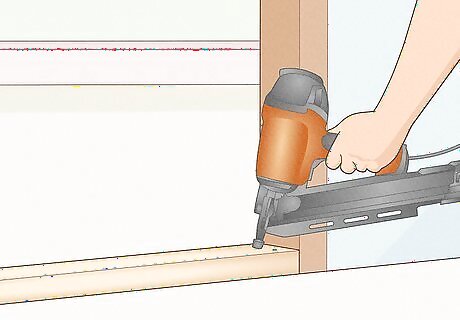

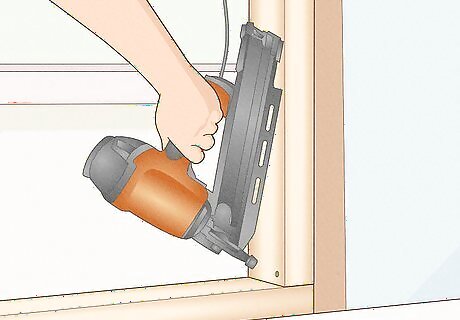

Screw or nail the wood boards down. Drive 2 nails or screws right next to each other at the corner of the bottom 2 in (5.1 cm) x 4 in (10 cm) board in the middle of the wood. Put 2 more at the center and then 2 in the opposite corner. Do the same for the top 2 in (5.1 cm) x 4 in (10 cm). If you have a nail gun, this job will be a lot easier. If you’re using power tools like a nail gun or drill, wear goggles to protect your eyes.

Placing the Studs

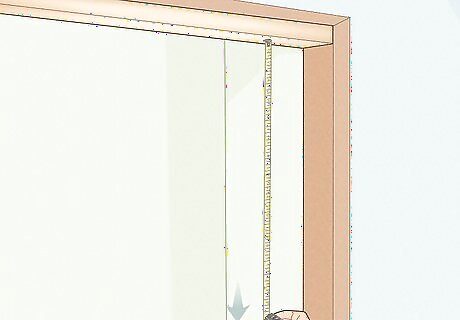

Measure the space on the sides of the door frame. Use your tape measure and check the space between the 2 in (5.1 cm) x 4 in (10 cm) boards. This should be the same on both sides, but check each side individually to make sure. Be sure you measure the space between the 2 in (5.1 cm) x 4 in (10 cm) boards or your measurement will be too long. A standard door is usually 78–80 in (200–200 cm) high. Your measurement will be at least 4 in (10 cm) less than that because of the 2 in (5.1 cm) x 4 in (10 cm) boards on the top and bottom.

Cut three 2 in (5.1 cm) x 4 in (10 cm) boards to the correct height. Mark the 2 in (5.1 cm) x 4 in (10 cm) boards to match the height of the space. Cut along the line with a saw to get a nice, straight cut. Remember to wear gloves and goggles while you’re using a saw. You’re cutting three boards this time because two are for the frame and one is for the stud in the middle.

Run a bead of caulk up each side of the frame. Hold your caulk gun in the lower corner of the door frame. Squeeze the trigger and run the gun up the side of the frame until you reach the top. Do the same for the other side.

Press 2 of the boards into the caulk. Take one board and slide it into the door space near one side. Align it with the edges of the frame, then press it down onto the caulk. Do the same for the other side. You might have to tap the boards with your hammer to get them into place.

Drive 2 nails or screws every 24 in (61 cm) up each side. Start at the bottom of one of the boards and drive 2 nails or screws right next to each other. Place another 2 every 24 in (61 cm) until you reach the top of the frame. Do the same for the other side. If you’re using a power tool like a drill or nail gun to do this, put your goggles on.

Place the third board directly in the middle of the opening. Measure the width of the space along the top and bottom boards. Divide your measurements in half to find the midpoint, and mark that point on the top and bottom boards. Then slide the third board into that spot. This forms the stud for the opening. For example, of the space is 32 in (81 cm) wide, then the midpoint is 16 in (41 cm). Mark this on the top and bottom boards and place the stud right on that point. If this is an outside-facing wall, then put some caulk on the top and bottom of the wood to make a tighter seal.

Toenail the stud to the top and bottom boards. Toenailing means to drive screws or nails in at an angle. Hold your drill or nail gun near the top of the stud at about a 45-degree angle with the board. Drive 2 nails or screws in at this angle. Then do the same for the bottom of the board to secure the stud. Toenailing is much easier with a nail gun or drill. It’s very difficult if you’re pounding the nails in by hand.

Filling the Space

Measure the dimensions of the frame. Use your tape measure and take the height and width of the opening, including the frame that you added. Make sure you include the 2 in (5.1 cm) x 4 in (10 cm) boards around the border of the frame, otherwise your wall coverings will be too small.

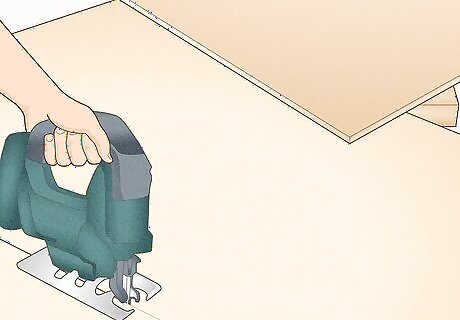

Cut 2 pieces of plywood or drywall to match those dimensions. Get the type of wallboard that’s already on the wall, which is probably plywood or drywall. Measure 2 boards to match the dimensions of the opening, and mark those measurements on the boards with a straightedge. Then cut along those lines with a saw so each board matches the door opening. Make sure you use wallboard that matches the wallboard that’s already there, including the thickness. Remember to wear goggles while you’re using a saw.

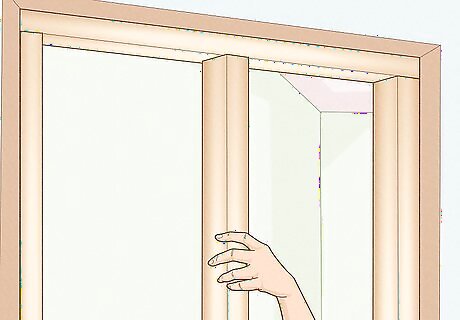

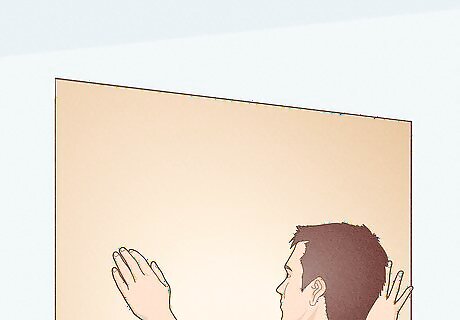

Hold the board against one side of the opening. It doesn’t matter which side you start on. Press one of the boards into the opening to make sure it fits against the frame and stud. It’s okay if the board doesn’t make a tight seal. You can seal any spaces later on.

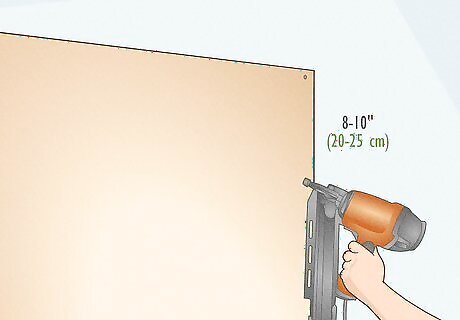

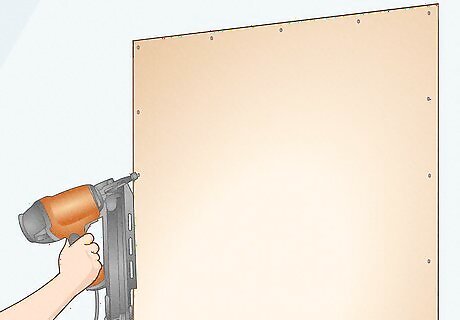

Drive nails or screws every 8–10 in (20–25 cm) along each stud. Start by placing a nail or screw in each corner of the board and one in the top and bottom edge into the middle stud. Then place one every 8–10 in (20–25 cm) along the border of the board and down the middle stud. The exact nail or screw length depends on the thickness of the panels you're using, but a standard nail or screw length for wall paneling is 1.5 inches (3.8 cm).

Stuff insulation into the wall opening. Cut 2 sheets of fiberglass insulation to fit between the studs in the wall opening. Press the sheets into position and staple them to the studs to hold them in place. Wear gloves, goggles, and a dust mask while you’re handling insulation. It could irritate your skin, eyes, and throat. It’s not as common to insulate interior walls, so if this opening doesn’t lead outside, then insulating is optional.

Attach the board to the other side of the wall to close the opening. Go to the other side of the wall and hold your final board up. Attach it to the wall by driving nails or screws every 8–10 in (20–25 cm) along the border of the board and down the middle stud. This closes up the door space.

Sealing the Gaps

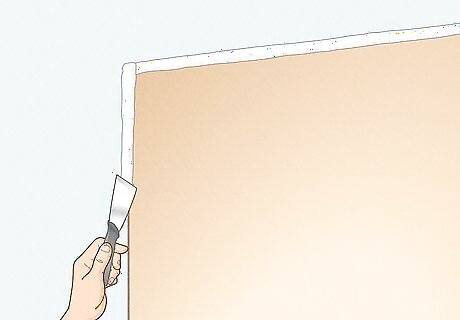

Fill the spaces around the frame with joint compound. Open up the container of joint compound and dip a putty knife in. Press the compound into the spaces around the door frame on both sides of the wall. When all the space is filled, press the knife along the spaces and scrape off any excess compound and smooth out the joints. You can also fill in any nail or screw holes with joint sealer too. Sand these spots down when it’s dry so the surface is nice and smooth. Joint compound is a common material that you can find at any hardware store. Different joint compounds might have specific instructions, so always check and follow those directions.

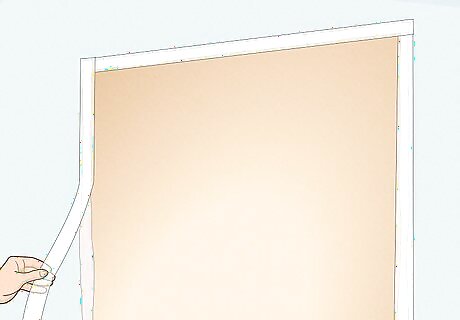

Cover the spaces with joint tape. Cut one piece of tape for each section of the frame. Press a strip along one of the joints and smooth it out with your putty knife so it’s flat. Repeat this for each side of the frame. Don’t substitute a different type of tape for joint tape. This won’t make a good seal. Remember to do this on both sides of the wall.

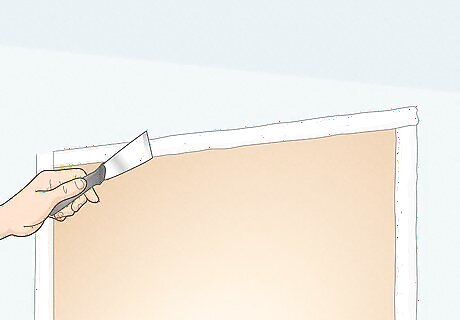

Apply another layer of joint compound to cover the tape. Scoop out the joint compound and scrape it onto the wall the same way you did before. Make sure the compound covers all the tape, then smooth it out with your putty knife.

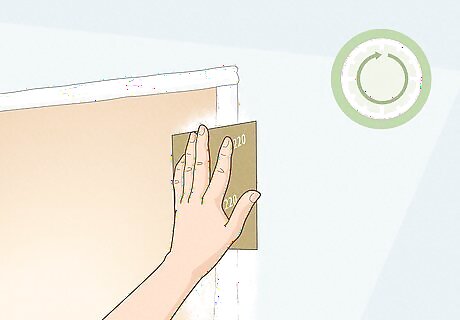

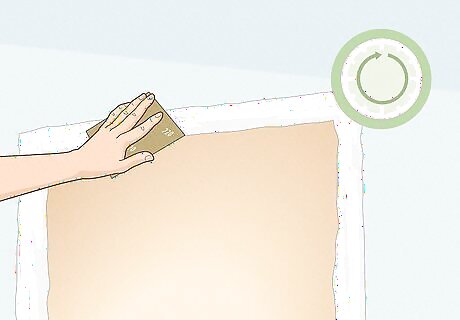

Sand the joint compound with 150- to 220-grit sandpaper after 24 hours. First, let the compound dry for 24 hours. When it’s dry, sand all the sealer with 150- to 220-grit sandpaper. Sand down any high spots and make sure the sealer is as even as possible with the surface of the wall. The product you use might have a different drying time, so be sure to check first.

Apply a final layer of compound. Scoop the compound out and scrape it against the wall along the same spots that you already sealed. Smooth it out with your putty knife when you’re done.

Smooth the compound with sandpaper after 24 hours. Let the compound dry for another 24 hours. After that, sand it again with 150- to 220-grit sandpaper until it’s nice and smooth.

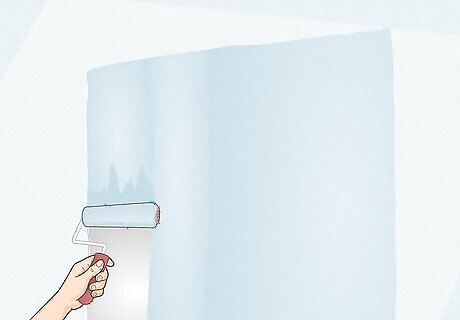

Paint over the board and joints if you want to. If you’re planning on painting over the new wall section, be sure to use paint that matches the surrounding wall. Then paint normally by sanding and priming first, and rolling the paint on. When you’re done, the new wall section should be nicely blended into the old one. Be certain to sand the joint compound well, otherwise, it will make an uneven finish when you paint. If one side is an exterior wall, then you can use house siding or the material that covers the exterior of your home.

Comments

0 comment