views

X

Research source

The price for an independent mechanic to replace a head gasket can be high due to the time-consuming labor involved, so, it is essential to know why you need to replace the head gasket. Have a professional ASE certified Master Auto Technician inspect your vehicle to conclusively determine whether or not your car needs to have the head gasket replaced. The purpose of this article is to help you learn how to install a head gasket to save money, but this should only be attempted by someone with a great deal of experience.

Obtain a service manual for your car's make and model. It will include step by step procedures with images that explain how to replace your head gasket(s). It will also list any special tools that you may need.

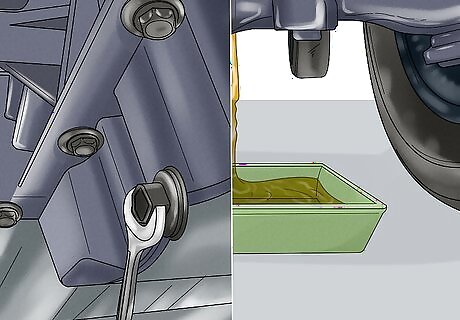

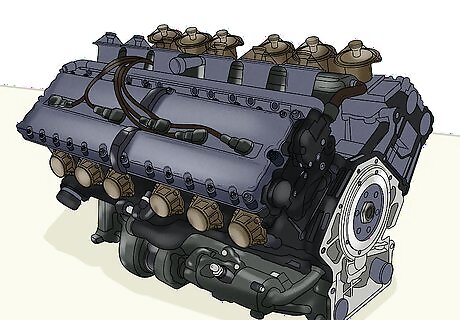

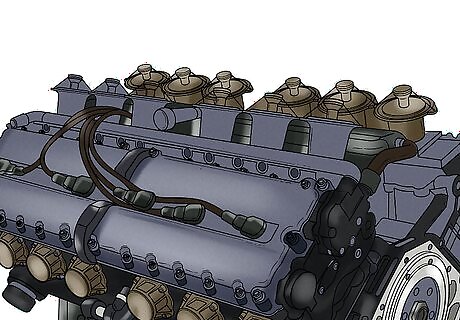

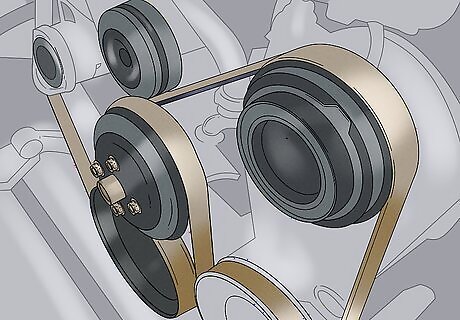

Drain all of the oil and coolant from your engine. Remove the parts that are connected to the cylinder head. Refer to your car's service manual for specifics, but in most cases this involves removing the exhaust manifold, the intake manifold, valve cover and drive belts. On many engines, you will need to remove the timing belt or timing chain. Be sure to study the timing belt/chain alignment procedures and be sure you clearly see the alignment marks before you disassemble the timing components. Catalog each part as it is removed. Either take pictures or write down each part to help you remember where everything goes once you're done. The cylinder head is held on by several bolts and some engines have a sequence for the bolts' removal. Some head bolts cannot be reused and must be replaced. Follow the manual and manufacture requirements. Once all head bolts are out then lift the cylinder head off of the engine block. Look at the head surface and the block along with the gasket for the failure areas. The gasket will be a thin piece of sealing material that can be seen once you remove the head. The gasket can be made out of metal, deformable material, or a combination of both. The failure can be a break in the gasket.

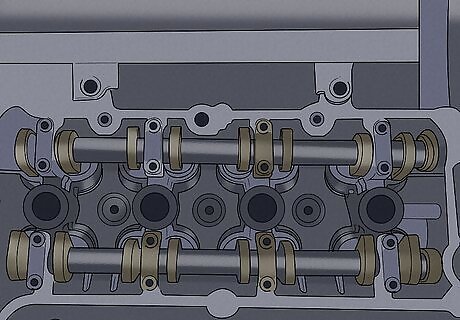

Check the block to be sure no warping has occurred and send the head or heads to an automotive machine shop to be pressure tested. If the pressure test reveals no cracks, have the machine shop resurface the head(s). Don't ever re-install a cylinder head that has not been professionally re-surfaced and examined for cracks. Check the service manual for the head bolt specifications to see if the bolts need to be replaced whenever the head gasket is replaced. Some bolts are what is called torque to yield type and would need to be replaced The cams on overhead cam motors will need the cams removed to service the cylinder heads. Talk to the machine shop that is working on your heads about what needs to be removed before having them work on them.

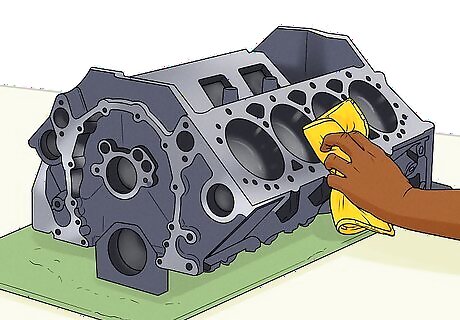

Clean the surface of the head and block. Do not scratch or remove any metal from either, as this may prevent the head gasket from sealing. Prevent any dirt or debris from getting into the cylinders or on pistons during the cleaning process. Inspect the piston tops and cylinder walls for any damage from the overheating or the head gasket problem. Make sure all surfaces are clean and dry.

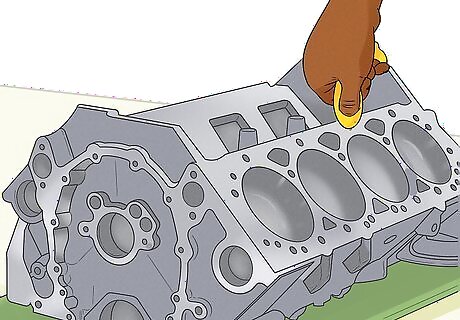

Clean the bolt holes that tighten the head to the block.

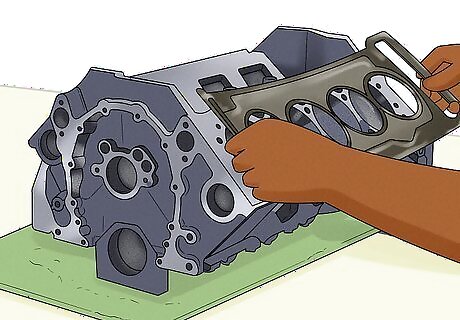

Fit the head gasket onto the block. Use gasket sealant when specified by the manufacturer, and only use the directed amount in the particular places. Deviating from the manufacturer's recommendations can cause damage to the internal parts of the engine. Most head gaskets will be marked "top" and "up" for proper installation.

Place the head onto the block with the head gasket in place.

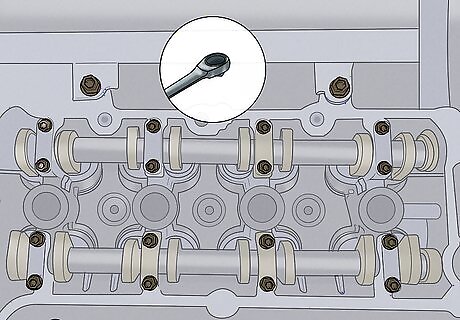

Use a torque wrench to tighten the head onto the block. Check the service manual for the head bolt torque sequence and the amount of torque that needs to be applied for each step. Some head bolts require 3 steps plus specified degree rotation as the final step. Overhead cam heads may need the cams to be in a set position before the head is installed, or installed after the head is installed to keep the valves from contacting the pistons and bending them.

Replace the other engine components you removed.

Set the timing belt or chain back to the proper alignment marks by carefully rotating the camshaft and crankshaft. Check to see if the engine is an interference type of engine. If so, there is a very specific method to rotate and set up the camshaft to crankshaft timing so you don't damage or bend the valves! If equipped, install the distributor so it is properly timed with the number one cylinder. If applicable, adjust the valve clearance to proper specification.

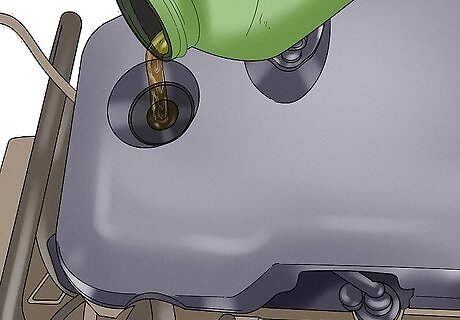

Fill the engine with new oil, replace the oil filter and fill the cooling system with new factory specified coolant. When you start the engine, be sure to let the engine idle with the heater on full blast. This is so the cooling system has a chance to bleed out any air bubbles. Some engines require a specific cooling system bleeding procedure, be sure to check for that. Make sure the engine does not overheat during the purging process, or head gasket or head damage could occur again. Once all air is out of the cooling system and engine temperature is stable and in the normal range, check for any leaking oil or coolant.

Comments

0 comment