views

Designing

Find a reference image. Use your favorite Internet search engine to find photographs of traditional knuckle dusters. Choose the best image and save it for use as a reference. The image you choose should clearly show the front side of the knuckle duster by itself. This image does not need to be to scale, but it should show an accurate outline. If you've memorized the way knuckle dusters look, you don't need to use a reference photograph. You can skip this step and move onto the next one if you feel comfortable doing so.

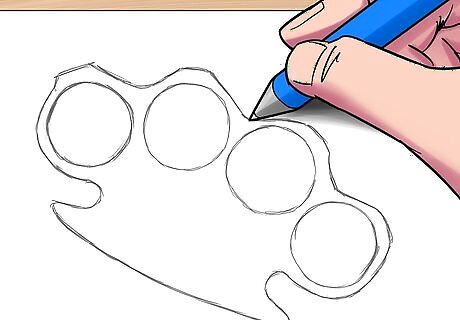

Sketch the design on paper. Using your reference image as a guide, sketch the design of your knuckle duster onto standard paper. You'll need to draw your design to scale, so it needs to be big enough to fit over your hand. For an average adult male's hand, the distance between the bottom of the middle finger holes and the bottom of the handle should be between 1.18 and 1.38 inches (30 and 35 mm). Each finger hole should be between 0.98 and 1.06 inches (25 and 27 mm). Instead of making perfect circles, try to make the holes slightly oval in shape. After sketching your design on paper, carefully cut it out. Cut around the perimeter of the design and cut out the holes, as well.

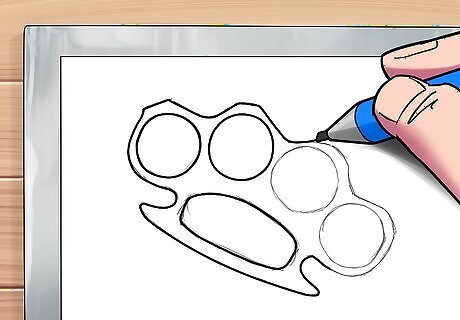

Trace the design onto the metal. Tape the paper design onto the metal you plan to use. Use a permanent marker to trace around the paper and create an outline on the metal. You may want to trace the design onto the metal using a pencil first. Doing so will allow you to correct any mistakes you make. Afterward, though, you should still trace over the same outline in permanent marker. After transferring the design to the metal, you can remove the paper pattern. Note that 2024 or 7075 aluminum, ¼ to ½ inch (7 to 12mm) thick, will be the easiest to find and work with. You can use actual brass measuring the same thickness, but the metal may give you more difficulties.

Cutting

Wear eye protection. Before you begin cutting into the metal, put on a pair of safety goggles. Since the metal will be tough to work through, there is some risk that a drill bit may snap off in the middle of the process. That bit could be hurdled toward your eyes and may cause injury if you leave your eyes unprotected.

Drill along the design pattern. Attach a ⅛ inch (3.2 mm) drill bit to a power drill, then drill along the entire outline on your metal. Drill along the perimeter of the overall design and around the perimeter of each hole you intend to make. The drill holes should be close but distinct. As a general rule, leave no more than half the diameter of the drill hole, roughly 1/16 inch (1.6 mm), in between separate holes. Do not overlap the holes since doing so may cause the bit to slip. Also note that you should use a corded power drill instead of a cordless one, if possible. A cordless power drill will be more likely to overheat, so you may need to take more breaks as you drill if you choose to use one.

Punch out the pattern. Place the tip of a flathead screwdriver on the metal in between separate holes, then use a hammer to strike the base of the screwdriver. Continue striking the screwdriver with the hammer until it breaks off the remaining metal. You'll need to repeat this around the entire pattern, breaking off the metal bridges in between drill holes one at a time. Punch around all of the previously made drill holes, including all exterior and interior ones. You may need to punch from both the back and front of the design. This part of the process can be very time consuming and will require plenty of physical strength. Note that you can cut the outside edge off in pieces using a hacksaw if you feel confident in your ability to control the direction of the machine around curved edges, but doing so is not necessary. You can punch the entire thing out using nothing but the hammer and screwdriver.

Push out the basic knuckle duster. After you've punched through the drill holes, you should be able to push the knuckle duster form out of the metal block using nothing but your fingers. At the completion of this step, you should be able to see the clearly defined knuckle duster shape. The edges will still be very rough, however, so handle the piece carefully. Recycle or otherwise reuse the remaining metal. It is no longer needed for the rest of this project.

Finishing

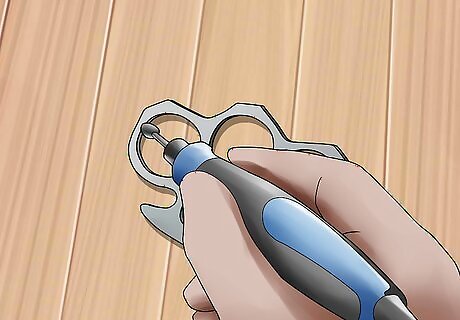

Smooth down the grooves. Use a Dremel-style rotary tool to smooth down the rough edges of the metal. Make sure that the tool has been fitted with a round bit designed for use with soft metal. If you inspect the edges of the knuckle duster, you should notice the presence of harsh grooves. The dip of each groove comes from the original drill holes you made, and the point corresponds with the punched-out space in between those holes. Focus the bit of the Dremel tool over the point of each groove. Sand down the point until it feels smooth and blends into the dip of the grooves around it. If you have difficulty filing down the edges, hold the knuckle duster in a vise grip as you work. Wedge a piece of paper or cloth in between the metal and the teeth of the grip to prevent the metal from getting scratched.

File the finer details. Once most of the metal grooves have been filed down, you can use metal files to make the edges even smoother. Use a round file to work on the grooves inside each finger hole and a triangle file to help create the notches in between the finger holes from the outside. You can use a flat file to work on the remainder of the outer edge. You can technically file down the entire knuckle duster without using a Dremel tool as long as you use these files to do it. Smoothing down the edges will be much more time consuming without the use of power tools, however, so it is not recommended. As before, you can hold the knuckle duster using a vice grip as you continue to file down the edges.

Sand the edges. Even though the edges should look notably more rounded after you finish filing them, you should still make them even smoother by grinding them down with sandpaper. You can sand the edges by hand. You do not need to use a sanding belt or other power tools for this part of the process. Work in steps. Start with a large grit sandpaper, like 60 or 80 grit, and work around the edges until you're satisfied with the results. Gradually work through different grits in this manner until you reach a fine grit like 320 or 400. If desired you can finish the sanding with fine-grit wet/dry sandpaper. Doing so is only optional, though, and may not be needed if the edge already seems smooth enough.

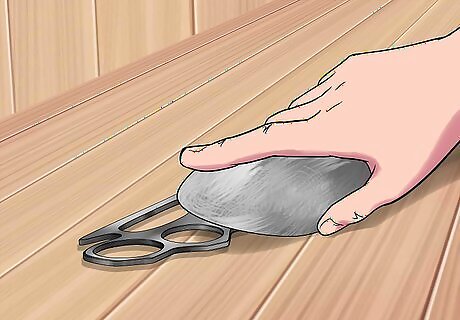

Buff the knuckle dusters. Grab a pad of #00 steel wool and buff the surface of the metal, working in small, circular motions. Work your way around the entire surface on both sides of the piece. You can buff over the edges, too, but doing so shouldn't be necessary at this point. Focus your energy and attention on buffing the flat metal surfaces during this step. When finished, the metal should appear less dull and more polished.

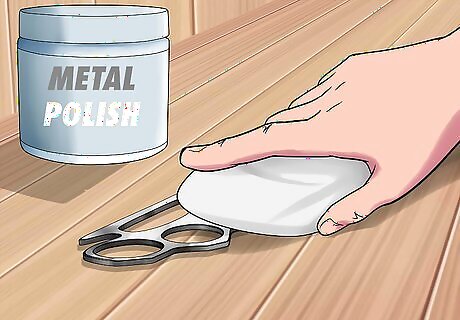

Apply metal polish. Spray or wipe metal cleaner over the entire piece, working over the flat surfaces and the edges. You can use either metal cleaner or metal polish. Either way, make sure that the product you choose is approved for use with aluminum so that you do not accidentally tarnish or otherwise damage the metal. Thoroughly work the product into the metal. Continue polishing and shining with a soft cloth until the surface of the metal is no longer moist from the cleaning spray.

Try them on. At this point, the knuckle dusters should be complete and ready to wear. Put them on and see how well they fit. Your fingers should fit comfortably into the finger holes and your hand should be able to bend over the base of the knuckle duster while it's on. You won't be able to make any changes to the piece if it is too loose, but if it feels too snug, you might be able to widen the finger holes slightly depending on how thick you left the metal around each hole. If you do make any changes, it is best to do so by filing the metal down with a Dremel tool or file instead of attempting to punch or saw it away.

Comments

0 comment