views

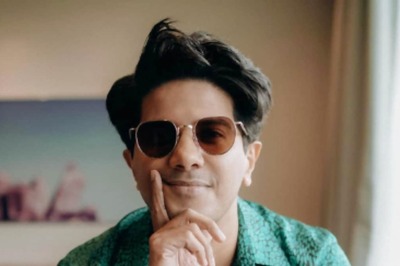

Name: Vikram Bakshi

Designation: CEO, McDonalds India (North and East)

The Challenge: To create the infrastructure to make the perfect McDonalds French fries in India

How He Did It: For nine years researched potato growing in India. Set up a processing plant in 2007

What Next? Source fish from India

In October 1996 we opened our first store at Vasant Vihar in New Delhi. There were long lines outside and this being an affluent neighbourhood, a lot of our customers had already tasted McDonald’s abroad. While we were very happy with the long lines outside our store, it became obvious very quickly that there was something wrong with the French fries we were serving. And customers began to notice too.

Worldwide, McDonald’s is known for producing what we proudly refer to as the gold standard as far as French fries are concerned. Our internal surveys have shown that 30 percent of customers come to our restaurants only to eat our fries. This is a huge number and we knew we could not afford to alienate them.

Those were also the days when foreign exchange was a scarce commodity. Before entering India we had promised the government that we would source everything locally. Now we had to go back on that promise.

In 1997 we asked the government for a small window to allow us to import fries. At the same time we assured them that we would go about developing systems within the country to produce these fries. The government agreed and our initial plan to set up a plant to make frozen French fries was scrapped.

Clearly the problem, and one we hadn't sufficiently anticipated, was with Indian potatoes. India is the world's third largest producer of potatoes but none of the varieties are suitable for producing the fries we needed.

In general, Indian potatoes have very high moisture content — between 85 percent and 88 percent. But to make French fries we also need a fairly high amount of solid content in the potato of about 22 percent to 24 percent. Unless you have these solids the French fries would soak up a lot of oil and get very limpy. That in one stroke takes away from the crispness. These potatoes are usually not grown in India.

Most potatoes are used for vegetable making in India and they hardly require these specifications. They are, at best, medium and round.

Another important requirement of our signature fries is the very large oblong shape. Medium and round won’t do; 200-250 grams in weight and about 4 inches to 6 inches is what we needed. And lastly, they need to have low sugar. Otherwise, while frying the sugar caramelises and it results in a brown tinge on the fries.

In 1997, we asked our global partners McCain Foods to extend their partnership to India and help us in developing the right kinds of potatoes in this part of the world. They agreed and set shop here with a team of two agronomists who started scouring the country for the ideal growing location.

Simply put, all that potatoes need to grow are long daylight hours, cool nights and sandy soil.

Cool nights mean that this is primarily a winter crop in India and between Punjab, Uttar Pradesh and West Bengal, about 90 percent of the country’s potatoes are grown.

First off, we had to make sure we had the right seeds. The Indian government does not allow importing seeds and so we brought in some saplings to Lahaul in Himachal Pradesh. It hardly rains in Lahaul and all water there is fresh from the glaciers. We chose Lahaul as we could grow these saplings in a pollution free environment.

Another advantage with Lahaul is that we are able to plant the seeds [that we got after planting the saplings] a lot quicker. Potato is a seasonal crop, usually harvested in March across India. The seeds are then stored for planting in November. In this case we plant the saplings in May in the hills and harvest them in September, making them ready to plant in November.

After several years of testing out locations in states across India we finally settled on Gujarat for two reasons. Firstly, this part of the country does not get any winter rain and the nights and early mornings are without fog, which causes the potatoes to sprout. Also, Gujarat farmers are among the most entrepreneurial in the country and are quick learners.

We introduced them to drip irrigation that helped save 30-50 percent of the water they would have otherwise consumed. Our yields per hectare are also 30-40 percent higher. All this took us seven years and by 2007 McCain was confident enough to invest $ 40 million and set up a plant in Mehsana, Gujarat.

Our job hardly ends once the potatoes are harvested. This is probably the most crucial stage and we tell our people that potatoes have to be handled like eggs - delicately. We realised that cold storage facilities in India were not up to scratch and had to set up our own. When potatoes are in storage they release a lot of carbon dioxide. That has to be pumped out and fresh air pumped in. Temperature also needs to be maintained.

If you keep temperature too high, the potatoes tend to sprout. Keep the temperature too low and they develop sugar. French fries with sugar become caramelised when fried.

Our restaurant managers are given complete autonomy to reject any consignment of frozen fries that does not meet our requirements. We take out a few random packets from each delivery and measure the fries. Forty percent must be above 4 inches, another 40 percent between 2 and 4 inches and the last 20 percent less than 2 inches. Deviating a percent or two is fine but anything more than that and we send the delivery back.

Making the right French fries is the first assignment we put our young recruits on. Our requirements are very strict and unless they learn how to make the right French fries we don’t move them on to the next assignment, which is frying patties. I still remember my training at Jakarta when we learned how to fry them at 168o centigrade for three minutes and 10 seconds to get the perfect colour.

Comments

0 comment