views

Examining the Base Material When Choosing Concrete Fasteners

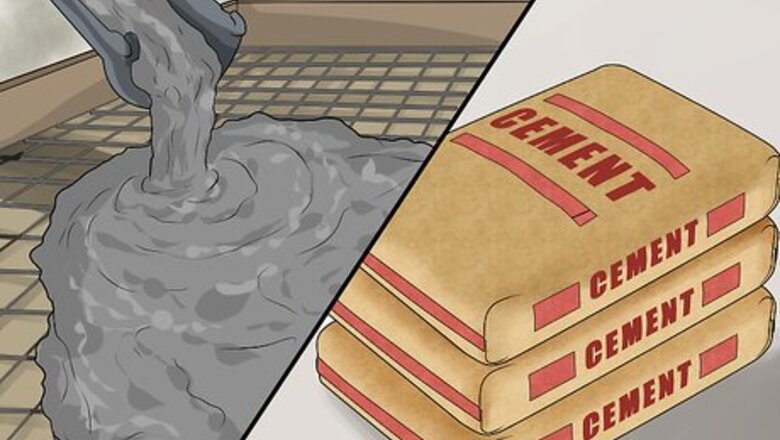

Understand the difference between concrete and cement. Concrete is made up of water, aggregates such as small stones and cement. Cement is merely an ingredient, not a base material on its own.

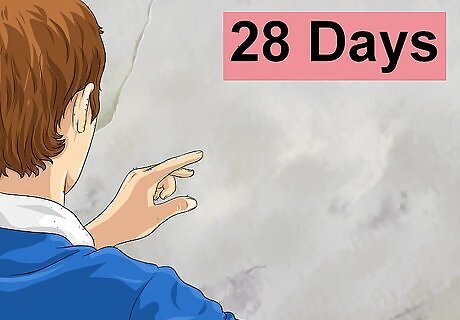

Consider the age of the concrete. Do not fasten or drill into concrete that is not older than 28 days. Look for an anchor that will drill into older concrete if it has aged. Certain anchors, such as the Tapcon screw, will not work on concrete that is old because lead threads can deteriorate and the screw will not go in deep enough.

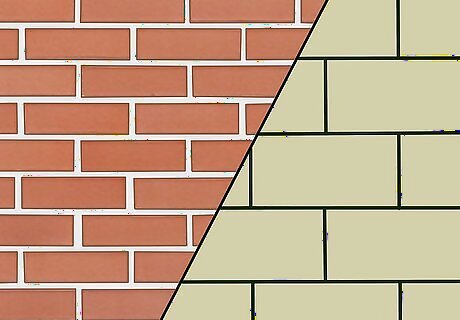

Find out if the base material is brick or block. These will use most of the same anchors as a concrete base, but a wedge anchor and a drop-in anchor should be avoided.

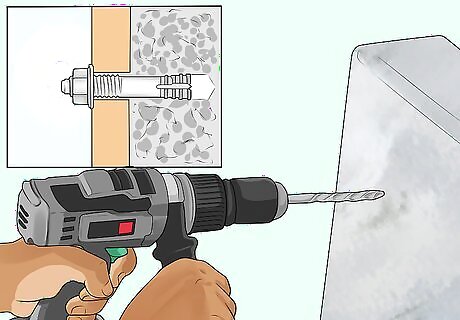

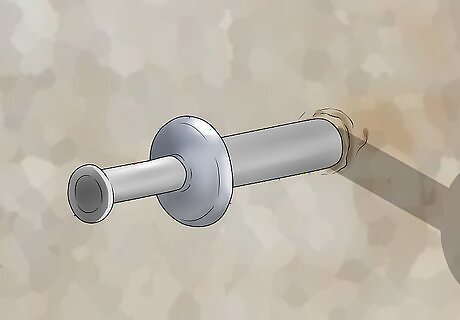

Consider the thickness of the concrete. You do not want the end of the fastener to get too close to the bottom of the concrete when you drill. This can create an unsupported edge which can reduce the amount of weight the concrete can hold.

Determining Weight When Choosing Concrete Fasteners

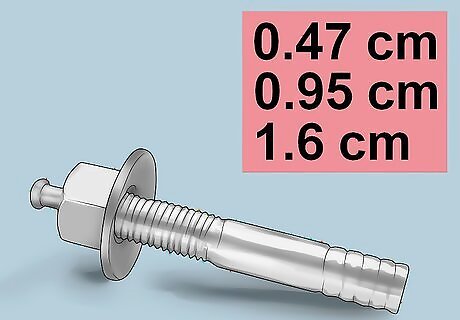

Determine the diameter of the fastener needed. This will depend on how heavy of an object is being fastened to concrete. Use a 3/16 inch (0.47 cm) or a 1/4 inch (0.63 cm) fastener for smaller, light objects that can be held while you fasten them to concrete. Use a 3/8 inch (0.95 cm), 1/2 inch (1.75 cm) or 5/8 inch (1.6 cm) diameter fastener on objects of medium weight, that require assistance from others to fasten to concrete. Use a fastener with a 5/8 inch (1.6 cm), 3/4 inch (1.9 cm) or 1 inch (2.54 cm) for heavy objects that must be mechanically fastened to concrete.

Embed the fastener deeper into the concrete for heavier objects. For example, a fastener with a 3/4 inch (1.9 cm) diameter will need to be screwed or drilled deeper than a fastener with a 3/16 inch (0.47 cm) diameter for proper holding.

Predicting Environment When Choosing Concrete Fasteners

Use standard zinc plated fasteners for concrete that will be indoors.

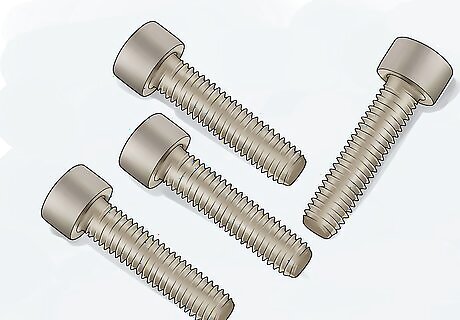

Try stainless steel fasteners for outdoor concrete. Zinc fasteners can be used, but stainless steel will do a better job of avoiding rust.

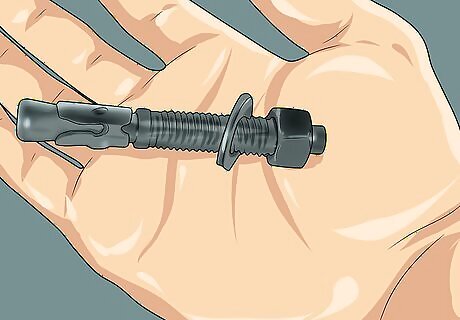

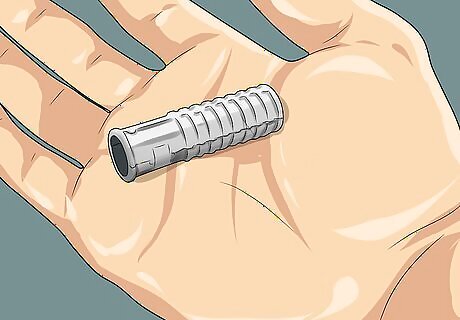

Protect the fastener from corrosion by using stainless steel products if the concrete will be exposed to chemicals. Look for stainless steel fasteners such as the Tapcon Screw, wedge anchor, sleeve anchor or drop-in anchor.

Choosing a Style of Concrete Fastener

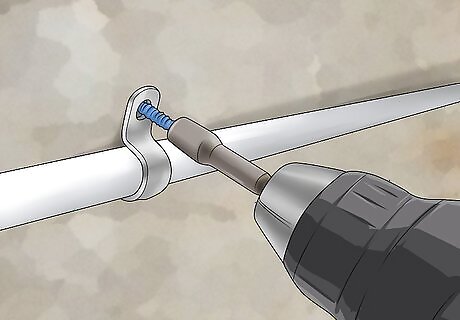

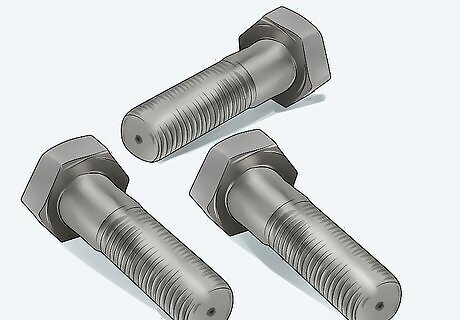

Use a male style of fastener if you prefer not to use setting tools or hole spotters. This type of fastener is inserted directly into a concrete hole.

Use a female style of fastener if the hole you use will be larger in diameter. A female fastener will have a screw or bolt drilled into it, and will require a setting tool and a hole spotter.

Consider whether a finished look is required. Some fasteners have an exposed steel rod sticking up through the nut.

Comments

0 comment