views

Using Heat to Remove Epoxy

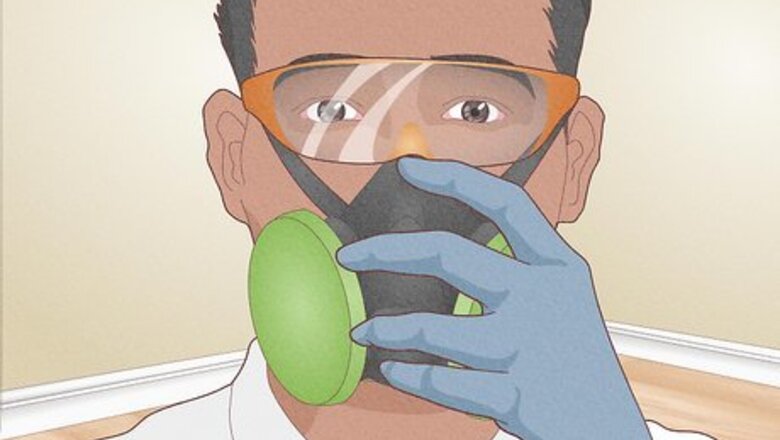

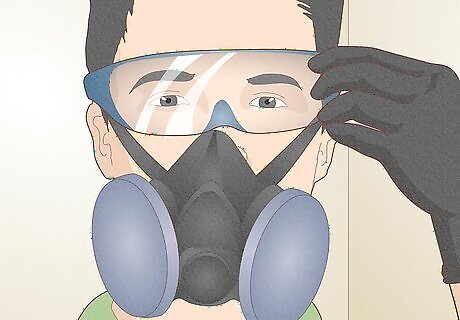

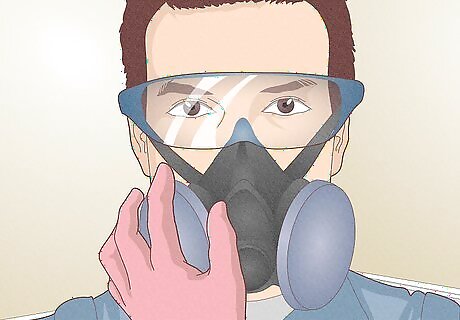

Put on gloves, goggles, and a respirator with gas and vapor cartridges. When you heat epoxy, it produces vapors that can irritate your eyes, lungs, and mucus membranes. To protect yourself, put on sealed safety goggles and a respirator that can filter out gases and vapors. You should also wear rubber gloves that extend at least 3 inches (7.6 cm) past your wrist to protect your skin, preferably with elastic bands to help create a seal.Tip: Respirator cartridges are color-coded according to what kind of filtration they provide. For example, if your epoxy contains organic vapors, use a cartridge that is coded black, yellow, or olive. The best type of respirator cartridge will depend on what your epoxy is made of. Check the Material Safety Data Sheet (MSDS) for your product to find out what type of respirator cartridge and other protective equipment you need. Make sure your goggles completely cover your eyes and sit flush against your skin, with no openings to let in air. Alternatively, you can use a PPE respirator mask with a built-in eye shield. Always test the mask for proper seal and fit. If you’re having trouble getting a good seal, you may need to trim any facial hair or get a better-fitting mask. If you smell any strong chemical odors while wearing your respirator, the respirator may not be working correctly or it may be time to replace the cartridge. Leave the area immediately so that you can inspect your respirator and make any necessary adjustments.

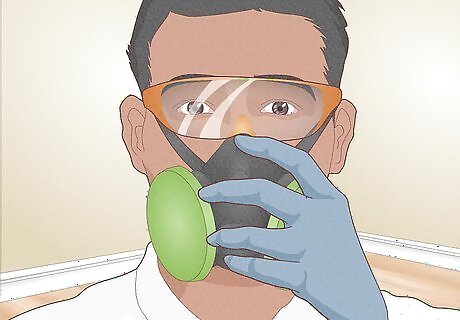

Wear clothes that cover your skin. Find a pair of tight pants and a tight fitting, long-sleeved shirt. If the shirt is a button-up, make sure all of the buttons are secure. This is meant to protect your skin from reacting to any vapors that may arise from heating the epoxy.

Soak the surface in acetone for at least 1 hour. If the epoxy is attached to a wooden surface, soak the area in acetone for an hour or more before using heat to soften the epoxy. You can either place the object in acetone or drip acetone onto the surface where the epoxy is set in. Acetone will only soak into a wooden surface. When dealing with epoxy on plastic, marble, cement, vinyl, or metal, any chemical will interact with the top of the surface, but they will not penetrate down into the layers like they do with wood.

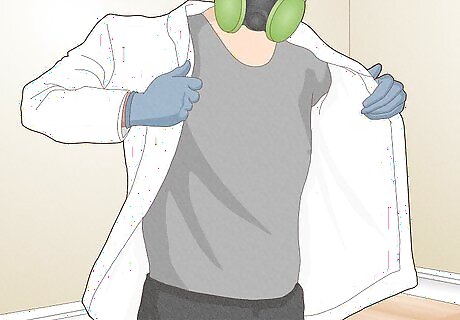

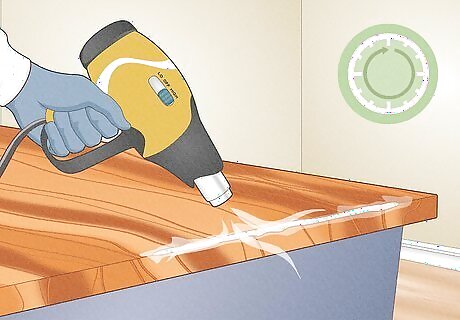

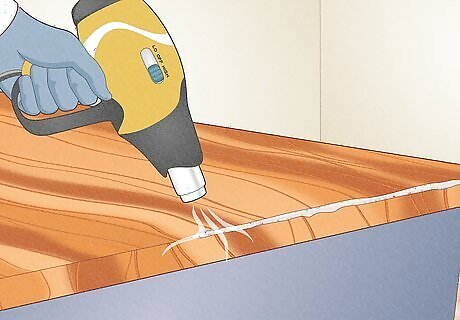

Aim a heat gun at the epoxy for several minutes. The objective is to raise the epoxy’s temperature to over 200 °F (93 °C), its softening point. Work the heat gun in small strokes rather than letting it stay at the same position for minutes at a time. If the epoxy is on a plastic or wooden surface, keep an eye on the surface so you don't warm it up too much and burn it. As an alternative to using a heat gun, you can use a soldering iron. After the iron is heated, apply it directly to a specific area of the epoxy bond line. This will soften the epoxy. If the epoxy you are seeking to heat is located on an object rather than the floor tiling, you can place the object on a hot plate. This will accomplish the same thing as the heat gun, and is more frequently available.

Heat small areas at a time. Don’t heat the entire bond line of epoxy at once or you won’t be able to keep the epoxy hot for long enough. Instead, work on segments that are about 2–3 inches (5.1–7.6 cm) in length. After you have one segment done, work on the segment right next to the first. It will be easier to scrape off with a now open edge.

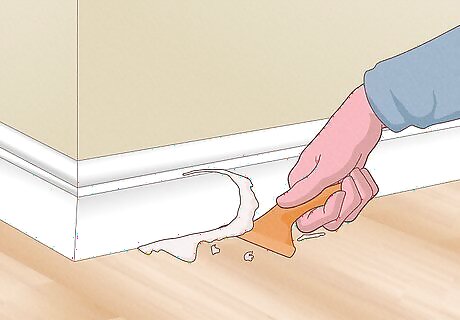

Scrape off the heated epoxy with a plastic scraper. Use a strong, plastic scraper to remove the epoxy from the surface. You may notice that the heat did not penetrate all the way down into all of the layers of epoxy. In this case, keep reheating the area and scrape until all the epoxy has been removed. Do not heat an area again right after you have already heated it. Wait a few minutes for the epoxy to cool off before you go back and reheat. Otherwise, you could cause the area to catch on fire. Do not use scrapers made of metal because they can easily cause damage to the surface you’re working on.

Freezing the Epoxy

Wear safety gloves, goggles, and a respirator mask with gas and vapor cartridges. Like the epoxy itself, refrigerants contain harmful vapors that can irritate your eyes, lungs, skin, and mucus membranes. Wear a pair of tight-fitting safety goggles that don’t let in any air, as well as a sealed respirator mask with gas and vapor cartridges. Put on a pair of rubber gloves that extend at least 3 inches (7.6 cm) past your wrists to protect your skin. Refer to the Material Safety Data Sheets (MSDS) for your refrigerant and the epoxy. These sheets will provide instructions on how to safety handle the materials and what kinds of protective equipment you need, including respirator cartridges. Consult a respirator guide, such as the 3M Cartridge and Filter Guide, to determine the correct color code for the type of respirator you need. Always research whether the refrigerant you plant to use is legal in your area. Some refrigerants are illegal to release due to environmental concerns!

Open your windows and doors. This allows air to move freely and carry vapors from the refrigerant outside. If you don't open your doors and windows, the fumes can build up and make it very dangerous to breathe the air. As the airflow is moving, you should place any kids and pets in a safe room with the door closed. This will prevent them from breathing in fumes. Make sure to turn your air conditioning or heating unit off so that it doesn’t pull the vapors in.

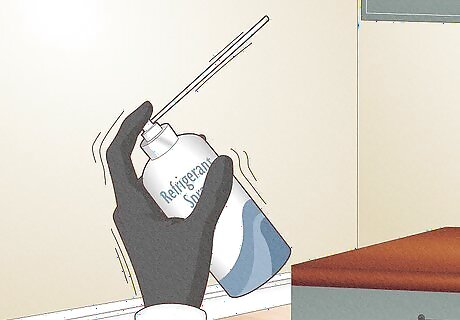

Shake your can of refrigerant. Refrigerant sprays can be found in multiple brands at most hardware stores. When you purchase a can, you will want to shake it before using it, just like any other spray can. Then hold it about 1 foot (30 cm) away from the epoxy you want to spray. Make sure you are holding the can upright, otherwise the liquid will leak out.

Spray your refrigerant on the epoxy. The spray will quickly drop the temperature of anything it touches. The epoxy will freeze and turn brittle. Do NOT put your hands near the area you are spraying. Make sure that your gloves and goggles are secure before you begin spraying. If you have children or pets, do not let them near the area.

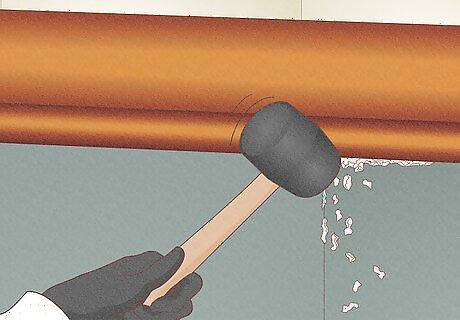

Chip away the brittle epoxy. Use a plastic putty knife or hit the epoxy with a rubber mallet or hammer. The epoxy should be cold enough that it turns to crystals and breaks off easily. You will then want to sweep the crystals up into a dustpan and immediately dump them into the trashcan. You can use a vacuum cleaner to make sure that you get rid of all of the remaining microscopic crystals. Be careful not to damage your surface by putting too much pressure on the epoxy. If it doesn't break apart easily, try adding more spray cooler to chill the resin even more.

Preparing Chemicals to Remove Epoxy

Put on goggles, safety gloves, and a respirator mask with gas and vapor cartridges. Before working with any chemical agents that can dissolve or soften epoxy, it’s vital to put on safety equipment that will protect your eyes, lungs, mucus membranes, and skin. Put on a pair of goggles that cover your eyes completely and sit flush against your skin, without any openings where air can get through. You’ll also need a respirator with appropriate cartridges for the chemicals you’re using, as well as rubber gloves that extend at least 3 inches (7.6 cm) past your wrists. Consult the Material Safety Data Sheets (MSDS) for your chemical solvents and epoxy so that you know what type of respirator cartridges you need.

Open up the windows and doors. This is incredibly important because you need airflow and ventilation. Air circulation through the open doors and windows will carry the harmful vapors of the chemicals towards the outside of your house. If your windows and doors remained closed, you will likely breathe in chemical agents which are hazardous to your health. Make sure to turn your air conditioning or heating unit off so that the fresh air doesn’t pull the vapors in.

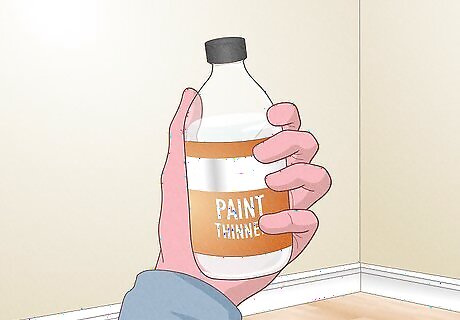

Choose a chemical that will soften epoxy. It is also critical that the chemical agent does not damage the surface that the epoxy is stuck on. Chemicals may damage certain surfaces such as cloth, plastic or vinyl. The strong chemicals may actually eat away at surfaces before they soften the epoxy glue. Always reference the Material Safety Data Sheets (MSDS) for all chemicals you are using! The MSDS will include handling instructions and list the correct Personal Protective Equipment (PPE) to use. Stay away from Class 3 and 4 oxidizers. These agents can cause spontaneous combustion or catch on fire down the road. Try a paint thinner. The acetone in most paint thinners can soften up hardened epoxy, but be prepared to let the epoxy and the object to which it is stuck soak for at least an hour. Use a commercial stripping agent. These are available at most hardware stores.

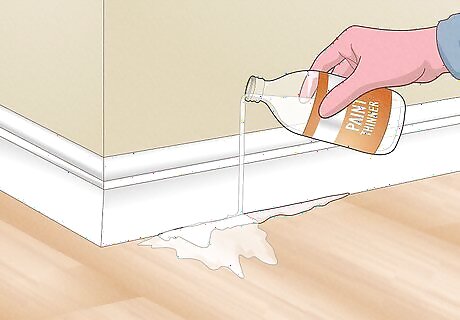

Apply the stripping agent. You can either drip some of the agent directly onto the epoxy or put some on a washcloth and dab the epoxy. Either way, make sure that enough agent makes its way onto the epoxy. After the agent has been applied, wait at least 1 hour before you come back to it. Work in small steps, 2–3 inches (5.1–7.6 cm) at a time. If the area is too wide, the chemical agent will likely not work as effectively. Make sure that children and pets are not around when you are applying the chemical agent.

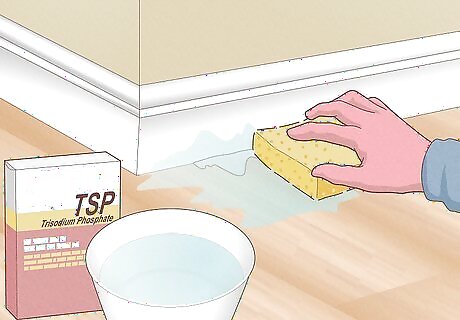

Mix a cleaning solution. After the chemical stripping agent sits for an hour, you will need to neutralize it before you scrape it off. In a medium sized bucket, mix together 2-3 tablespoons (50-75 g) of trisodium phosphate and 1 gallon (3.8 L) of hot water. You can either pour the mixture onto the stripping agent or dab it on with a sponge. Let it sit and neutralize the agent for at least 5 minutes.

Scrape the epoxy resin from the surface. Scrape the resin off with a sharp, strong, plastic scraper. You will want to immediately place the epoxy in a paper towel and throw it away in a trash can. The goal is to not let the chemical agents get anywhere near you. If some epoxy is still stuck to the surface, soak the remaining epoxy in the chemical for a while longer before trying to scrape it off. When you have scraped the epoxy off, wash the area down with a rag soaked in warm water and soap. You do not want the chemicals to linger around, especially with children and pets in the house.

Comments

0 comment