views

Filling Hairline Cracks and Chips

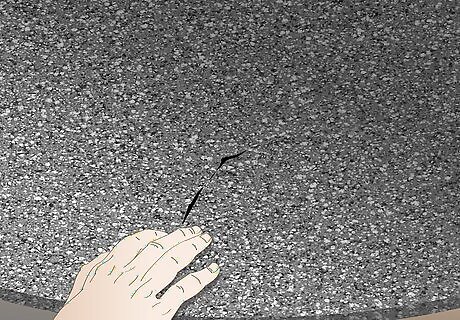

Determine whether the crack or chip needs to be repaired at all. Small surface cracks and chips that don't go all the way through the granite can be unsightly, but they don't pose a threat to the longevity of your granite surface. In fact, small cracks that go with the grain of the granite, called fissures, are a normal aspect of the stone. If you can only see a hairline crack from a very specific angle and you can't feel it when you run your hand across the surface, then it is likely that the crack is completely harmless and can be left alone. To ensure that these small imperfections do not become more unsightly, be sure to seal your granite regularly, usually once a year.

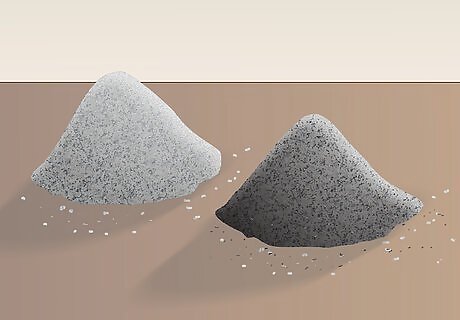

Collect matching granite dust. In order to make the repair blend in with the rest of the slab, you will need to color the glue to match it. This is done by using some of the granite to color the glue. To create granite dust, use a grinder with a diamond grinding bit to go over the surface of a matching piece of granite. The fine dust created is what you will use. You will need no more than 2 teaspoons of granite powder to repair most cracks under 1 foot (0.30 m) long. If you have an extra piece of the counter top material, you can use this. You can also remove a bit of granite dust from an area that is not visible, such as the underside of a counter top. Wear a dust mask that is rated for this type of particulate.

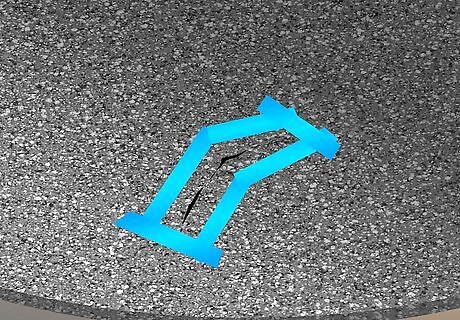

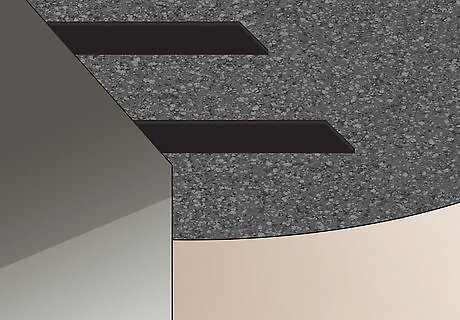

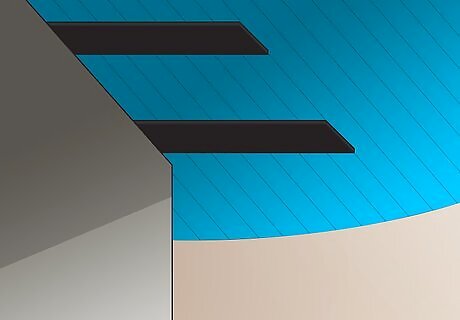

Mask off the area. Cover the area all around the chip or crack so that the filler will not get all over the surface. Use painter's tape or any other tape product that can hold up to epoxy or resin, and yet will come off the granite easily when you are done. Mask off to within ⁄8 inch (0.32 cm) around the whole crack or chip so that cleaning up will be easier.

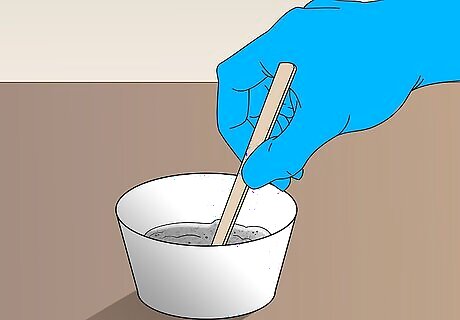

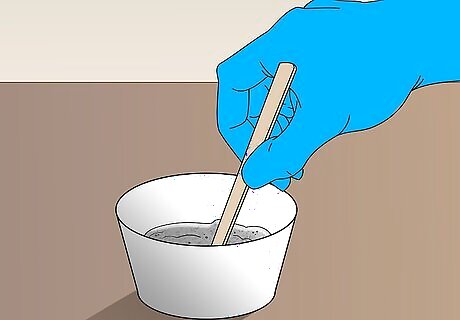

Mix 2-part epoxy and the granite dust. Follow the directions supplied with the epoxy you are using, which typically includes mixing a set amount of each part of the epoxy with each other. Then add the granite dust until the product is a thick paste that is the same general color as the granite. Pick an epoxy that states on its packaging that it can be used for granite or stone repair. Use a wooden paint mixer or other disposable tool with at least 1 flat side to mix the epoxy. Tongue depressors work exceptionally well for this job. This tool will then also be used for applying the epoxy to the crack.

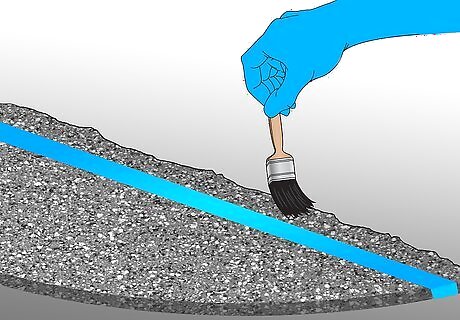

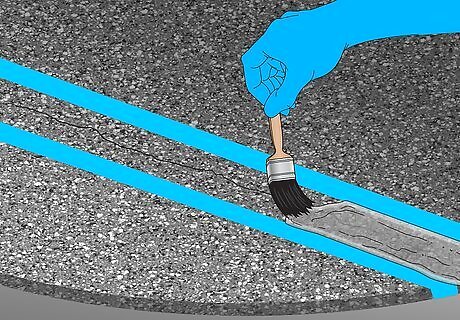

Apply the epoxy. Smear the epoxy into the crack or chip until it is filled. You can do this with the tool you used to mix the epoxy. Then smooth it out as much as you can, as any bumps will need to be sanded down. The epoxy does tend to shrink a bit while drying, so it's better to over-fill the crack than to under-fill it.

Reattaching Broken Pieces

Support the broken section. Many times the pieces that break off of granite counter tops are not supported well. If this is the case, you need to find a way to support the broken piece during and after the repair. This will allow you to make a secure repair and will fix the problem that caused the break in the first place. For example, if an overhanging piece of granite has snapped off, you will need to install a metal support under the overhang to hold the granite up. This can be a piece of angle iron or other L-shaped bracket that can hold the granite's weight during and after the repair.

Tape off all surrounding surfaces. Since you will be using a strong glue to reattach the granite, it's important to mask off surrounding surfaces. This includes all of the granite counter top that surrounds the crack. Use painter's tape or a similar product to do the masking. The product should be able to stand up to the glue you are using but still be easily removed in the end. Masking completely will also help you if you need to remove the counter top or surfaces around it in the future. For example, keeping the glue off a sink in the counter top will ensure that the sink can be removed in the future without damaging the counter top.

Clean all of the connecting surfaces. When reattaching a piece of broken granite, you need to make sure all of the surfaces are free of dirt and loose debris. This includes granite dust that may have been created when the piece broke off. Brush off any loose pieces and then use acetone or another residue free cleaner to wipe down the surfaces. Let this surface dry before proceeding with the reattachment.

Mix the epoxy with matching granite dust. In order to get a seam that blends in, you want to incorporate some of the granite into the epoxy. First mix the epoxy as directed on its packaging. Then blend in the granite dust until the mixture becomes a thick paste that is the same color as the existing granite. Create the granite dust with a grinder, either by grinding a section of the granite that is not normally visible or grinding a spare piece you have lying around. Use a wood paint stick or other disposable tool, such as a disposable plastic knife, to mix the epoxy and dust mixture.

Apply the first coat of epoxy. Once all the surfaces are clean and dry, you can begin applying the adhesive. Use the tool you used to mix the epoxy to apply it to all the surfaces individually. Then stick the surfaces together. If large amounts of epoxy ooze out of the crack, wipe these off with a disposable rag. Follow the application directions supplied with the epoxy. However, most epoxy products require you to apply the adhesive on all surfaces before sticking them together. This coat is used strictly to glue the broken surfaces back together. Another coat of epoxy will be used to smooth out the top surface of the crack.

Shim and tape the area. Once the broken piece is reapplied, you want to make sure that it dries in the right spot. To do this, put shims under it to ensure it is at the same level as the larger piece it broke off of. Also tape it in place with more painter's tape if it needs more support. Also make sure that everyone in your household knows not to touch the area for the next day or so. Having someone knock into the repaired area before it is dry could create a larger repair problem.

Apply a second coat of epoxy. When repairing complete breaks, you will need to apply a second coat of epoxy to smooth out the top surface. Mix up a new batch of epoxy, including the granite dust, and smooth it into the crack. With this coat focus on getting the surface as smooth as possible, as any bumps or imperfections will take some effort to buff out. This is necessary because your first coat will shrink as it dries. This shrinkage will create a slight dip at the crack that the second coat will fill.

Finishing Crack Repairs or Reattachments

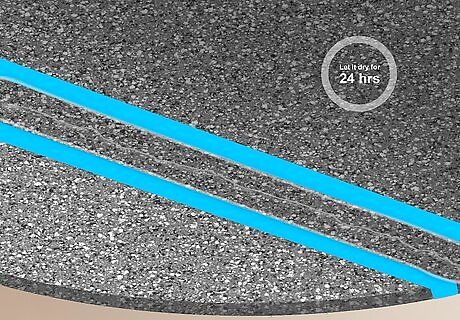

Allow the epoxy to dry. Drying times for epoxy vary depending on the brand and the type. Follow the drying times on the package the epoxy came in to ensure that it is solid before moving forward. The drying time for epoxy used to repair granite is typically around 24 hours.

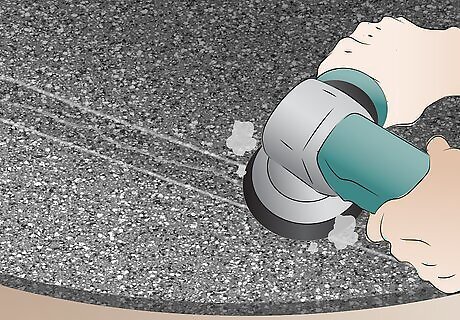

Clean and buff the surface. Remove the masking and assess the area. Use a razor blade to clean off any irregularities in the patch. Then use your buffing wheels to gradually build up the shine on the repaired area. When buffing your repair, start with wet buffing pads and move through the grits, from 100 grit to 3000 grit. With each pad you should work on the area until it is a consistent smoothness, and then move on to the next finer pad. After going through the wet buffing pads, start with the dry buffing pads. Start with a 400 grit pad and work your way through to a 3000 grit pad.

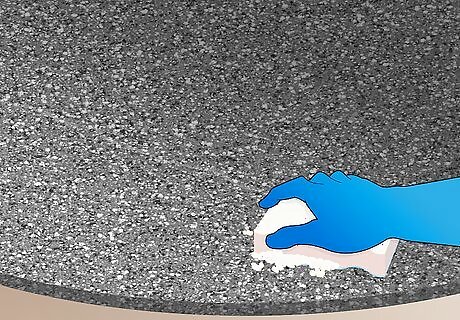

Use tin oxide to shine the surface. If you want to get the area really shiny, you can use tin oxide, also known as lapidary polish, to buff out the area. Put on rubber or latex gloves and put a small amount of tin oxide on a felt pad. Then rub the area by hand for about 10 minutes. After that, wipe the area off with a paper towel and surface cleaner to see the whole area shine. Tin oxide is available online from lapidary suppliers. Tin oxide comes in a variety of colors, so pick one that closely matches the color of your granite.

Preventing Cracks Through Proper Installation

Support the underside of the counter top. When granite is installed, it should have solid supports installed underneath the entirety of it. This could be any type of solid, rigid base, such as ⁄4 inch (1.9 cm) plywood or concrete board. There are specialty brackets available online that are made to support granite overhangs, such as those used to create eating areas at the end of counter tops.

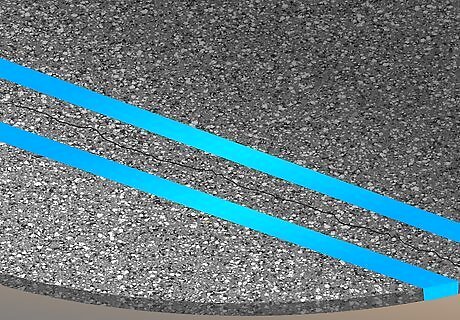

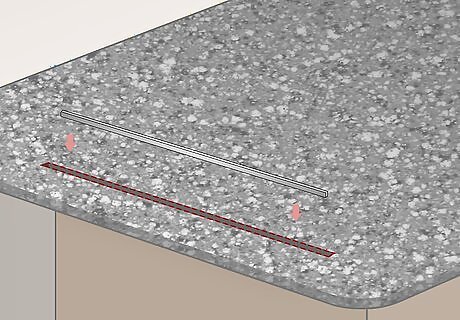

Apply rods along the underside of cutout edges. Granite counter tops often crack in narrow stretches that are not as strong as the rest of the slab. In these areas, such as areas in front or behind a sink, it's a good idea to apply a steel rod or metal strip to give these narrow areas added strength. Granite fabricators can do this in their shops. They will cut a slot for the rod to sit in and then epoxy it in place. Talk to your fabricator about this option before having new counter tops cut to shape.

Have an experienced professional install your granite. Don't have a general contractor or handyman do the job. Instead, hire someone whose entire job is installing granite, as they will have a deeper understanding of the material and how to install it correctly. If you want to install granite yourself, talk to a professional or 2 before moving forward with the project. They may be able to give you key advice about your specific project, including what pitfalls to avoid.

Comments

0 comment