views

Servicing Disc Brakes

Loosen the lugs. While the car is on the ground, you should use a lug wrench or an impact wrench to loosen the lug nuts. Doing it this way prevents the tires from spinning. This helps break the lugs loose more efficiently and more safely.

Jack up the car. Consult your service manual for safe jacking points. Slide the jack under the car and position it directly under the jacking point. Jack the car up and secure it with jack stands.

Remove the wheels. Now that the car is lifted, the weight will no longer be on the tires. You can finish removing the lugs either by hand or with your wrench. Then, simply slide the wheel away from the wheelbase. You should always slide the wheel underneath the car. This adds an extra layer of safety if the jack stands fail.

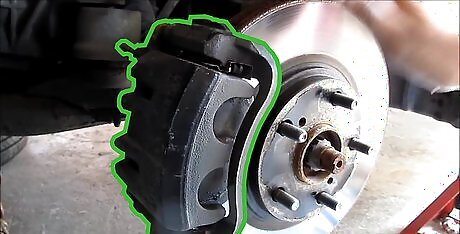

Locate the brake caliper. Now that you have the wheel off, you will be looking directly at your brake rotor. Mounted on the rotor (usually to the right) you will see your brake caliper. The brake caliper holds the brake pads against the rotor on either side.

Remove the brake caliper as a single unit. Brake calipers differ slightly from car to car, but they are always held in place by bolts or clips. These are usually located at the top and bottom of the caliper. Once the bolts and/or clips are removed, the caliper can be pulled away from the rotor. You do not need to disconnect the brake line from the caliper, but you should tie it up with wire or cord so that it doesn’t get kinked or damaged.

Inspect the brake pads for wear or damage. Some brake pads have a groove in the middle that serves as an indicator for wear. If the groove is nearly gone, the pads are in need of changing. In any case, if the pad is less than ¼ inch thick or is chipped or damaged, it needs replaced. To avoid break failure make sure that brake pads thickness is over three millimeters.

Make note of any damage on the calipers. Your calipers should not need replaced, as they are designed to last for the life of the car. That being said, if there is damage on the caliper it might need replaced. Also, it is possible that the bolts or pins that hold the caliper in place could be damaged. If this is the case you will need to replace those.

Take a close look at the brake rotor. The brake disc, or rotor, is another important part of the braking system. When the brakes are applied, the pads press down on the rotor to create the friction needed for stopping. This generates a lot of pressure and heat. If your rotors are not thick enough, or if they have grooves or chips in them, they will need to be replaced. Minimum rotor thickness is generally stamped on the outside of the disc and can be measured using a micrometer, a side caliper, or a tape measurer.The micrometer is the easiest and most accurate measurement.

Servicing Drum Brakes

Remove the wheels. The drum brake is located behind the wheel. Once the wheel is out of the way, you will have access to the brake drum.

Remove the drum. Removing the drum will provide you access to the inner workings of your brakes, which are mounted on the backing plate. To do this, you will need to first remove the dust cap in the center. Underneath, there will be a retaining nut and cotter pin. Use pliers to remove the cotter pin and a socket to remove the nut. The drum should now slide off. If you have trouble sliding the drum off, check to be sure there are not additional bolts or clips holding it to the hub. It is possible for the brake shoes to get stuck against the drum. In this case, you will need to remove the rubber plug on the back of the backing plate to gain access to the brake shoe adjuster. Use a flathead screwdriver or brake adjuster bar to retract them.

Inspect the brake shoes. The brake shoe liners should not be less than the minimum recommended thickness. For the leading brake shoe (the one closest to the front of the car) this is usually around 1/8 inch. For the trailing brake shoe (the one closest to the back of the car) this is usually around 7/64 inch. Check your service manual for your car’s exact specifications and replace any brake liners that do not meet that standard.

Identify and inspect your return springs. These springs are responsible for returning the brake shoes to their proper resting location after you remove your foot from the brake pedal. It is important that these springs are not damaged or loose. As long as the springs are still tight and are not damaged or overly rusted, you can continue to use them. If you need to remove the springs to replace them, or so that you can remove and replace your brake shoes, using brake spring pliers can make this a breeze.

Change your wheel cylinder. It is best practice to change the wheel cylinder anytime you have the brake drums off. The brakes will continue to work as long as the cylinder does not leak or stick, but it is impossible to look at the cylinder and determine how much wear is on the inside. To replace the wheel cylinder, you will need to first remove the brake line with a wrench. Next, unbolt the cylinder from the backing plate by removing the one or two bolts that hold it there. Install the new cylinder by bolting it into place where the original was, and then connecting the brake line.

Inspecting and Servicing the Hydraulic Brake System

Locate the master cylinder. This is the reservoir tank that stores brake fluid. It is located under the hood on the driver’s side firewall.

Look for brake fluid on the outside of the master cylinder. This will indicate that the master cylinder is leaking. This will result in too little brake fluid in the system and will reduce your stopping power. Not having enough will result in a weak or spongy brake.

Check your brake fluid. Hydraulic braking fluid is the medium that allows force to be transferred from the brake pedal to the brake. Remove the lid from the master cylinder and look inside. The brake fluid should be all the way up to the “Full” line. If it is not, you will need to add brake fluid and follow any air purging techniques that your service manual recommends. Do not let dirt or other contaminants fall into the master cylinder. This will compromise your brake system. When your done checking your brake fluid, replace the master cylinder cap. You should also change your brake fluid as often as your owner’s manual recommends, otherwise it may absorb moisture from the air that corrodes the system and lowers the pressure inside the brake lines by allowing the fluid to boil.

Check your brake lines. If you have rubber brake lines, make sure that there are no punctures, leaks, or deterioration along the entire length of the line. If you have metal brake lines, you should also check for corrosion or rust. If you see any of these signs of deteriorating brake lines, you will need to replace your lines.

Comments

0 comment